- Contact Us

-

Contact: Devin Liu

E-mail: sales@sheetmetal-fabrication.com

Tel: +86 13382165719

Wechat: LGQ4169719 Contact Now

Contact Now

- New Products

- Latest News

-

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the custom design and fabrication of stainless steel, iron, aluminum, galvanized sheet and other materials. The fabricatio...what is advantage of anodic oxidation and anodized ?

Anodizing (spelled anodizing, in Singapore, the UK, India, and Australia) is an electrolytic passivation process used to increase the thickness of the...China Internation Furniture Fair 2017

From September 11 to 14, 2017, the 40th CIFF Shanghai will present a fantastic feast for the furniture and home furnishings industry. CIFF features th...How coronavirus impact global economy?

The coronavirus outbreak, which originated in China, has infected more than 200,000 people. Its spread has left businesses around the world counting c...

- Subscribe

-

Get email updates on new products

China Manufacturer Brake Drum Price Semi Trailer Brake Drums

- Model: K8-018

- Material: Bimetallic Composite Brake Drum

- Braking Surface

- Shell Thickness: 5.5mm

- Grey Iron Thickness: 13mm

- Tensile Strength of Circumferential Section 1mm: 5060N

- Yield Force of Circumferential Section 1mm: 1402.5N

- Elongation: Yes

- Tensile Strength of Circumferential Section 1mm Lift over Conventional: 1.11

- Flange Root

- Shell Thickness: 12.5mm

- Tensile Strength of Circumferential Section 1mm: 5000N

- Circumferential section 1mm Yield: 3187.5N

- Elongation: Yes

- Circumferential section 1mm Tensile strength over conventional lift: 1.157

Optimize your semi-trailer's performance and safety with top-tier brake drums sourced directly from leading manufacturers in China. As a premier China rear drum brakes manufacturer, we specialize in engineering robust brake drums specifically designed for the rigorous demands of semi-trailers. Our products are forged from high-grade cast iron, ensuring exceptional heat dissipation, resistance to warping, and extended service life under heavy loads and frequent braking cycles.

Precision manufacturing guarantees perfect fitment and reliable operation, crucial for maintaining optimal braking efficiency and reducing costly downtime. We understand the critical role reliable rear drum brakes play in fleet safety and operational costs. That's why, as your trusted China rear drum brakes supplier, we offer rigorous quality control adhering to internationally recognized standards (like TUV, ISO), ensuring every drum meets stringent performance and safety benchmarks.

Partner with us for unbeatable value. We combine superior manufacturing expertise with competitive pricing, delivering the durability and performance your fleet requires without compromise. Choose confidence on the road. Choose premium China rear drum brakes engineered for the long haul. Contact us today for quotes and experience the difference quality makes.

Product Specification

| Model | K8-018 | |

| Material | Bimetallic Composite | |

| Braking Surface | Shell Thickness | 5.5mm |

| Grey Iron Thickness | 13mm | |

| Tensile Strength of Circumferential Section 1mm | 5060N | |

| Yield Force of Circumferential Section 1mm | 1402.5N | |

| Elongation | Yes | |

| Tensile Strength of Circumferential Section 1mm Lift over Conventional | 1.11 | |

| Flange Root | Shell Thickness | 12.5mm |

| Tensile Strength of Circumferential Section 1mm | 5000N | |

| Yield Force of Circumferential Section 1mm | 3187.5N | |

| Elongation | Yes | |

| Tensile Strength of Circumferential Section 1mm Lift over Conventional | 1.157 | |

Product Pictures

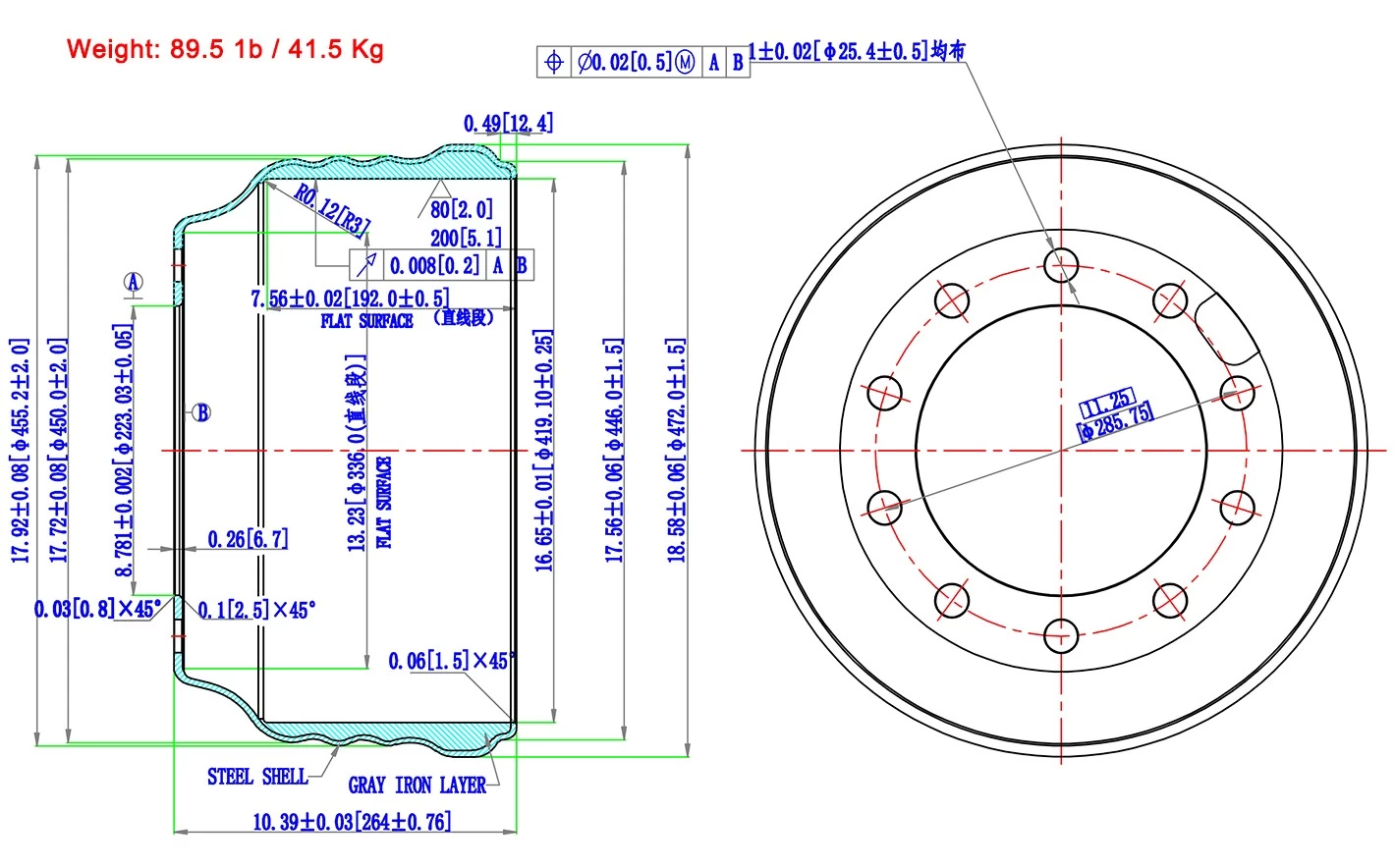

Product Dimension

FAQ

Q: What is a tandem drum brake?

A: A tandem drum brake is a single brake assembly (typically on the rear axle) where two separate pairs of brake shoes are mounted concentrically inside one brake drum. Each pair is actuated by its own hydraulic wheel cylinder (primary and secondary), often working in tandem for increased braking force or to serve different functions (service brake and parking brake).

Q: How does a tandem drum brake work?

A: Hydraulic pressure from the master cylinder is applied to both wheel cylinders simultaneously. The primary cylinder pushes the leading (front) shoes outward against the drum. The secondary cylinder pushes the trailing (rear) shoes outward. The rotation of the drum creates a self-energizing effect, wedging the shoes tighter for more force. Often, one set (usually the secondary) is also linked to the parking brake mechanism.

Q: Why is it important to replace brake shoes in axle sets?

A: Brake shoes should always be replaced on both wheels of the same axle at the same time. Replacing only one side creates an imbalance in braking force, leading to dangerous vehicle pulling during braking, uneven tire wear, and potential instability.

Q: How is the parking brake integrated with a tandem drum brake?

A: The parking brake cable usually connects directly to the lever on the secondary brake shoe assembly. Applying the parking brake mechanically forces the secondary shoes outward against the drum, locking the wheel. This is why parking brake issues often point to problems within the drum brake assembly itself.

Q: Are tandem drum brakes still used on modern cars?

A: While less common than in the past, yes. They are still frequently found on the rear axle of many economy cars, trucks, and SUVs, primarily due to the ease of integrating the parking brake and cost-effectiveness. Front brakes are almost universally disc brakes on modern vehicles for superior performance.

Q: What are the disadvantages of tandem drum brakes?

A: Main disadvantages include: Heat Dissipation: Drums trap heat more than ventilated discs, leading to brake fade under heavy or repeated braking.

Wet Weather Performance: Water ingress can cause longer stopping distances until friction dries the surfaces.

Complexity: More moving parts (springs, levers, adjusters) than disc calipers, making servicing potentially more involved.

Self-Adjustment Issues: Self-adjusters can stick or fail, leading to reduced brake performance or dragging.

Slower Response: Generally exhibit slightly longer pedal travel and response time compared to discs.

Tel:8613382165719

Wechat:LGQ4169719

Facebook:ahlgq2000@163.com

Contact Person:Devin Liu

PDF Show:PDF