Houdry is a China sheet metal fabrication manufacturer that provides professional and efficient laser cutting service. With industry-leading laser cutting equipment, we have a diverse range of processing capabilities to accurately cut a wide variety of metals. Our experienced technical team ensures that every product meets stringent process standards, efficiently meeting your needs from precision parts to high-volume production.

If you are looking for China laser cutting parts suppliers, choosing Houdry is to choose reliable quality, excellent efficiency and one-stop service! Welcome to inquire!

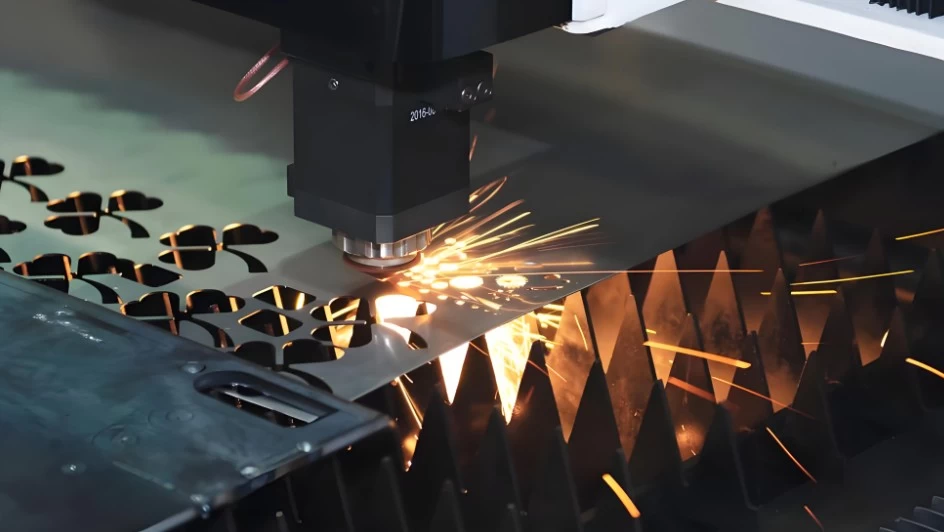

In the era of pursuing precision manufacturing and design innovation, laser cutting technology has become the core processing means of modern sheet metal processing in China by virtue of its unparalleled precision, efficiency and flexibility. It utilizes high energy density laser beams to achieve fine and fast cutting of metal materials, and accurately transforms your ideas and designs into reality.

What is laser cutting?

Laser cutting is a kind of precision processing technology that uses a high power density laser beam to irradiate the surface of the material, so that the material rapidly melts, vaporizes or reaches the ignition point, and at the same time blows away the melted or burned material with a high-pressure gas (e.g., nitrogen, oxygen, argon) to realize the separation of the material. It is like an invisible, extremely accurate and highly concentrated energy “light knife”, through the CNC numerical control technology, laser can be in a variety of metal materials (such as stainless steel, carbon steel, aluminum alloy, copper, etc.) above the cutting out of complex shapes.

Precision Metal Laser Cutting Services - Stainless Steel, Carbon Steel, Aluminum & More

China Laser cutting service can handle a wide range of metal materials, as can Houdry. Whether you need to cut stainless steel, carbon steel, aluminum, copper, titanium, or any other common metal, our state-of-the-art laser equipment and skilled team can ensure that your project is completed with precision and efficiency for everything from simple parts to complex geometries. Explore our specialized cutting capabilities for different materials:

1. Stainless Steel Laser Cutting Service

ss laser cutting is very common in sheet metal fabrication, because stainless steel is widely used in kitchenware, medical equipment, architectural decoration and industrial parts, etc. due to its corrosion resistance, high strength and beautiful appearance. Our stainless steel cutting service can cut all kinds of stainless steel (such as 304, 316, etc.), and can handle workpieces with thicknesses ranging from thin to 1.5 inches; our high-precision laser cutting process can achieve a smooth kerf and minimal thermal deformation, maximizing the protection of stainless steel material's original properties, stainless steel Our high-precision laser cutting process provides smooth cuts with minimal thermal distortion, maximizing the original properties of stainless steel.

2. Carbon Steel Laser Cutting Service

Houdry has a state-of-the-art carbon steel laser cutting service that efficiently performs precision cutting on carbon steel parts. Utilizing high power fiber laser cutting machines, we are able to achieve superior accuracy and neat edges on carbon steel sheets, processing thicknesses typically from gauge to 1 inch or thicker. This process ensures minimal material distortion, burr-free cuts, and tight tolerances, making it ideal for complex shapes, intricate designs, and high-volume production.

Whether you need a simple bracket, a complex mechanical part, a structural component, or a customized prototype in a common steel grade such as 1018, A36, or 1045, our laser cutting provides a fast, reliable, and cost-effective solution to your carbon steel fabrication needs.

3. Aluminum Laser Cutting Service

Aluminum is ideal for many industrial applications due to its light weight, excellent thermal conductivity and good recyclability. However, the highly reflective nature of aluminum poses a significant challenge in the aluminum cutting service, and Houdry's laser cutting machines are equipped with innovative solutions for highly reflective materials, enabling efficient, precise and clean cutting of aluminum alloys of all sizes.

Houdry's superior performance in the aluminum laser cutting service with precise cut control and effective reduction of slag and thermal distortion has made us attractive to customers in areas where cut quality and accuracy are critical, such as automotive parts manufacturing, high-performance radiator production, precision aerospace component machining, and consumer electronics enclosure manufacturing, among others. etc.

4. Copper Laser Cutting Services

Copper and its alloys (e.g. brass, bronze) have excellent electrical, thermal and ductile conductivity and are commonly used for electrical components, decorative parts and heat exchangers. Their high reflectivity and thermal conductivity require specific cutting parameters. Our copper laser cutting services, using the appropriate laser wavelength and gas assistance, enable fine, oxidation-free cutting of copper with little effect on the electrical conductivity of the cut, perfectly meeting the high standards of the electronics industry and precision engineering.

5. Titanium Laser Cutting Service

Titanium alloys are indispensable for aerospace, medical implants and high-end chemicals due to their high strength-to-weight ratio, excellent corrosion resistance and biocompatibility. titanium laser cutting service requires strict control of the heat input to prevent degradation of the material properties. Our inert gas shielded cutting technology allows us to cut titanium alloys from thin to medium-thick plates with high quality, clean cuts and no oxidative discoloration, ensuring that the material's outstanding properties are preserved.

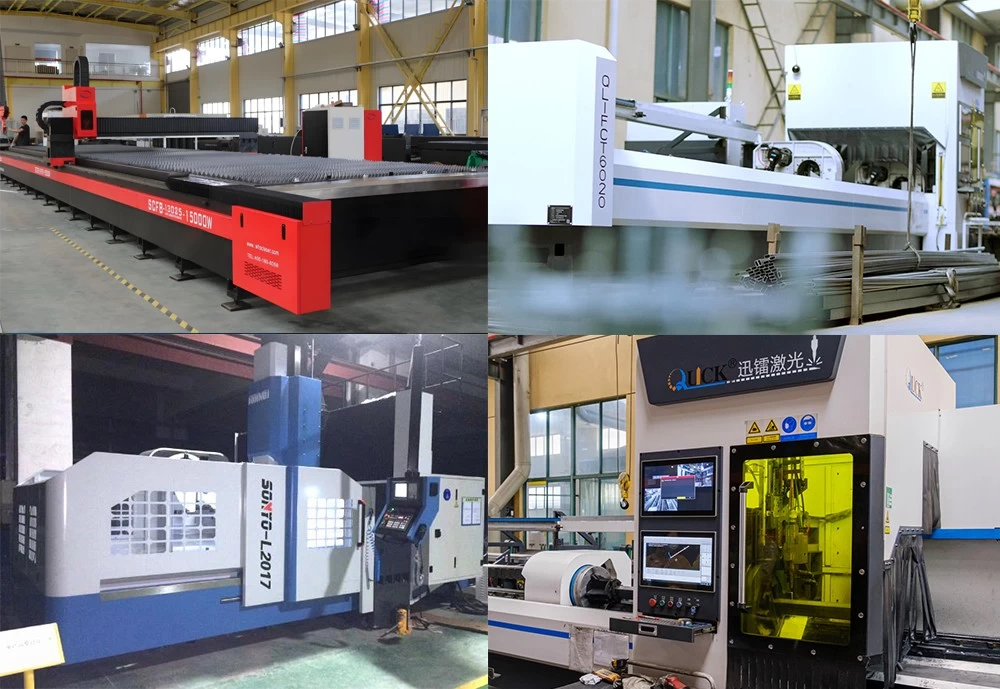

Houdry Laser Cutting Equipment Display

As China's leading laser cutting service supplier, we know that reliable equipment is the foundation of high-quality services. We have also invested in cutting-edge processing equipment for this purpose. It is not only a guarantee of productivity, but also the core competitiveness of quality, speed and coping with complex process challenges. The following are the equipment that can be used for laser cutting services:

Laser cutting machine:

Houdry has a total of 5 laser cutting machines (excluding plasma cutting machines and water jet cutting machines), which are responsible for thin plates and medium and thick plates respectively.

1 is a high-power (≥12000W) laser cutting machine, which is mainly responsible for thick plates (such as ≥15mm carbon steel, stainless steel) and high-speed cutting of thin plates.

3 medium and high power (6000W - 10000W) laser cutting machines are the main models of our laser cutting services, taking into account efficiency, cost and wide material adaptability; with fiber laser technology and high-precision control systems, it has become the only choice for complex graphics and high-demand workpieces with its high precision, high efficiency and high flexibility. It includes large-scale laser cutting machines, providing a large-size processing table of 4*12 meters to meet the processing needs of large workpieces.

1 is a medium-power (3000W - 5000W) laser cutting machine, which focuses on high-speed cutting of thin plates (<6mm), precision micro-machining or pipe cutting.

Houdry sheet metal processing factory has technicians with rich experience in cutting parameters, optimizing the process for different material thicknesses to ensure the best cutting quality. Professional quality engineers track the quality of the whole process and detect key dimensions to ensure that each product meets the requirements.

China Custom Laser Cutting Process?

For customers who are new to laser cutting services, it is crucial to understand our specific processes and key links, helping customers quickly master all aspects from demand communication to finished product delivery, reduce communication costs, and optimize production collaboration. The following is the laser cutting process of Houdry sheet metal processing plant:

1. Demand communication

The customer provides drawings/samples (vector files such as DXF/DWG/AI/SVG) or 3D models. Confirm the material type, thickness, size and surface treatment requirements with the customer.

2. Quotation confirmation

Quotation based on the material, working hours and quantity of the confirmed drawings, and confirm the quotation and delivery date with the customer.

3. File processing

The engineer checks the feasibility of the drawings and generates the cutting path through programming (need to confirm the details with the customer).

4. Processing and production

Loading (metal), adjusting the parameters of the laser cutting machine (power/speed), and starting automatic cutting.

5. Post-processing

The cut laser-cut sheet metal parts are deburred/cleaned according to customer needs, and the relevant quality inspection department conducts quality inspection and checks the dimensional accuracy.

6. Delivery

The laser-cut sheet metal parts are packaged and shipped.

Why Choose Houdry Laser Cutting Service?

1. High precision and advanced technology

Houdry's laser cutting service uses a fiber laser system, which is suitable for cutting a variety of materials (stainless steel, carbon steel, aluminum and copper, etc.), with millimeter or even micron precision, smooth edges, and reduced subsequent processing requirements. It can also be equipped with an automated system (such as a robot arm or CNC control) to handle complex geometries and is suitable for demanding industrial applications.

2. Wide range of material applicability

Houdry's laser cutting service can cut metals such as stainless steel, aluminum, titanium, copper, and some non-metallic materials, meeting the needs of multiple industries such as aerospace, automobiles, and electronics. Customized solutions can also be provided, such as thin or thick plate cutting (for example, metals above 15mm).

3. Efficiency and cost advantages

Houdry has 5 laser cutting equipment with fast delivery, especially suitable for large-volume order production; high efficiency and low cost. It has a 4*12 meter large platform cutting machine to meet the processing needs of large workpieces.

4. Quality Control and Certification

As a sheet metal processing manufacturer with multiple international certifications, Houdry strictly follows global industry standards to ensure product quality and compliance: we have obtained ISO9001: 2015, ISO13485:2016, ISO14001:2015, IATF16949:2016, UL, ROSH, CE and other certificates.

5. Additional Service Support

Strong Engineering Team Service: Houdry has 25 process engineers who can help customers optimize drawings to save materials or improve efficiency.

Post-processing integration: One-stop service such as deburring and polishing.

Whether you are in the field of mechanical manufacturing, electronic communications, medical equipment, architectural decoration or creative design, Houdry's professional laser cutting service is your trusted partner. We are committed to solving complex metal cutting problems for you with advanced equipment, exquisite craftsmanship and reliable services, improving product competitiveness and accelerating project success.

Contact Houdry now to get exclusive laser cutting service solutions and quotes!