In the world of sheet metal manufacturing, welding is like a silent vein that tightly links scattered metal parts, giving strength and form to the design. From the solid skeleton of an elevator car to the precise shell of a medical device, from the tight encapsulation of a telecommunication cabinet to the solid frame of an industrial equipment - every precise welding is a silent promise of product reliability.

As a welding sheet metal fabrication manufacturer in China, Houdry understands the decisive influence of welding technology on the final quality. With advanced robotic welding equipments and profound craftsmanship, we are committed to be your reliable sheet metal welding services supplier.

If you are looking for sheet metal fabrication and welding supplier, choosing Houdry is to choose reliable quality, excellent efficiency and one-stop service! Welcome to inquire!

What is welding?

Welding is essentially a fabrication process that permanently joins separated metallic materials at the atomic level by applying heat or pressure (or both). It's like “bone-setting” for metals:

Tough Joint: Creates a high-strength metallurgical bond at the joint that far exceeds the mechanical strength of a riveted or bolted joint.

Structural unity: Seamlessly integrates multiple individual parts into a structurally sound, uniformly stressed whole.

Precise sealing: Realize reliable air- or water-tight sealing between sheet metal parts.

Design Freedom: Provides the possibility of realizing sheet metal products with complex shapes and structures.

At Houdry, sheet metal welding is more than just “bonding”, it is an essential part of the precision manufacturing process.

Houdry Sheet Metal Welding Services

Houdry offers a full range of sheet metal welding services, covering a wide range of needs from simple components to complex assemblies.

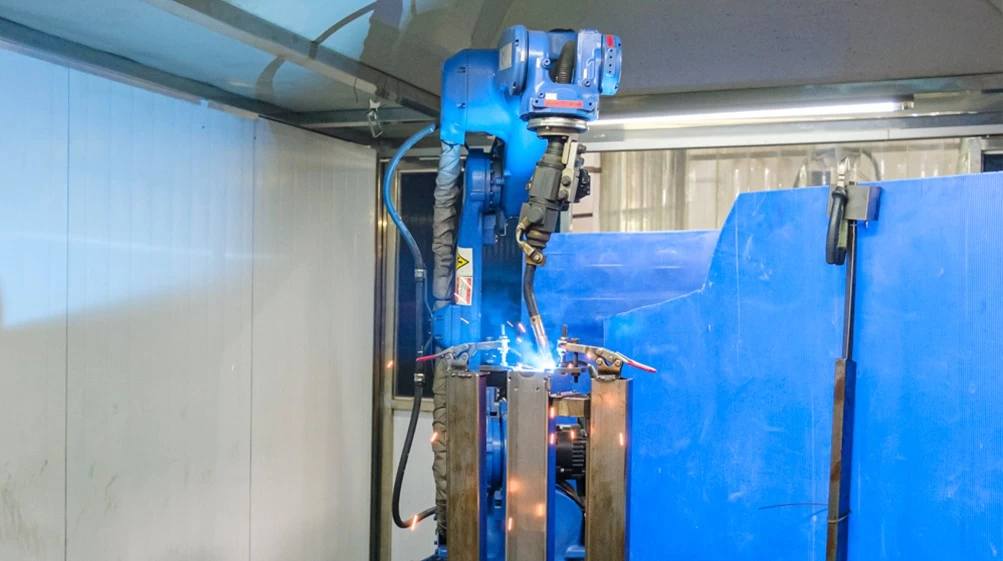

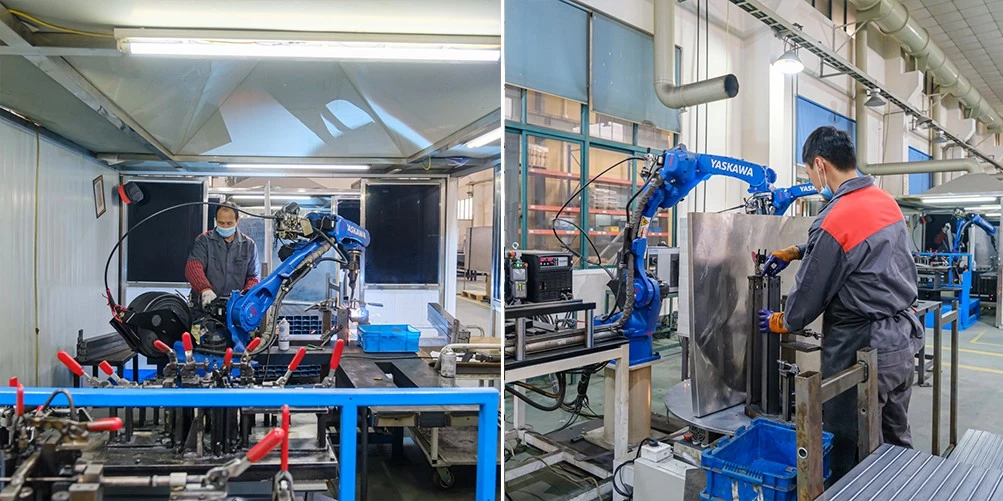

1. Advanced Robot Welding:

Houdry's sheet metal welding service utilizes advanced robot welding technology. Equipped with high-precision, multi-axis linkage welding robot system, it ensures that each welding trajectory is precise and accurate, and complex structures can also be perfectly realized. Robot welding parameters are constant, completely avoiding manual fluctuations, guaranteeing stable and reliable welding quality for each product, and realizing “zero-difference” manufacturing. And also greatly enhance the efficiency, our robot welding 7 * 24 hours efficient continuous production, choose China Houdry sheet metal welding services, is to choose a short delivery time, to help you quickly and quickly seize the market.

2. Diversified welding process proficiency:

Houdry as China sheet metal welding services factory can provide efficient and flexible MIG/MAG welding (applicable to carbon steel, stainless steel and other thin and medium-thickness plate, high deposition efficiency, deformation control); the pursuit of the ultimate beauty and purity of the weld seam of the TIG welding (specializing in stainless steel, aluminum alloys, to meet the medical equipment, Food equipment and other demanding occasions); as well as focusing on high energy density laser welding (to achieve ultra-high speed, very small heat-affected zone and deformation of the precision welding, suitable for microelectronics, precision instruments and other cutting-edge fields), Houdry's sheet metal welding services can comprehensively cover your precision manufacturing needs.

3. Stringent Quality Assurance System:

In the process of sheet metal welding services, we strictly implement real-time monitoring of the welding process (parameter records can be traced), fusion of professional inspection (VT/PT, etc. to ensure that the weld seam is free of defects), and on-demand strength verification (destructive or non-destructive testing), to build up reliable quality barriers from the source to the end, so that your products will last and be free of worries.

4. Wide range of material applications:

Chinaquality sheet metal & welding has already maturely mastered the welding characteristics and process points of many commonly used sheet metal materials such as mild steel, stainless steel (304, 316, etc.), aluminum alloy and so on. No matter what kind of metal material you have, Houdry can provide sheet metal welding service.

Houdry's Sheet Metal Welding Equipment

Houdry, as a China sheet metal welding service supplier, in order to meet the demand for efficient and high-quality sheet metal welding production, we have 20 welding stations with the following equipment:

Robotic Welding Workstations (10 Units): Robotic welding is the core of our factory to improve the quality and stability, production efficiency and reduce the overall cost, which is mainly applied to large-volume and highly repetitive It is mainly used in large-volume, highly repetitive key welds (such as cabinets, brackets, etc.) to realize accurate and continuous operation.

Semi-automatic Gas Shielded Welding Equipment (MIG/MAG, TIG) (6 units): Manual welding units that provide excellent flexibility and adaptability to cover a wide range of welding tasks, ideal for complex workpieces or small batch production.

Spot / Projection Welding Machines (3 units): Spot welding machines are highly efficient in solving specific joining requirements in sheet metal welding, ensuring reliable and fast joining of specific structural parts (e.g. sheet metal parts, wire assemblies).

Laser Welding Machine (On-demand: 1 set): The laser welding machine can meet the high-end solution for high-precision welding or special materials (e.g., sheet metal, dissimilar metals), and satisfy application scenarios with stringent requirements for weld seam quality and heat-affected zone control.

Why choose Houdry as your sheet metal welding supplier?

Robot Welding: Robot welding brings not only efficiency, but also millimeter precision positioning and millisecond stability control, providing your products with a reliable quality cornerstone that exceeds the limits of manual labor.

Automated production: The automated production mode fundamentally eliminates human fluctuations, ensuring consistent weld quality for every product in a batch order, giving you confidence in the final delivery.

Cost Reduction and Efficiency Increase: High-speed continuous operation of robots significantly shortens the production cycle, and large-scale production effectively dilutes the cost per piece, providing you with more competitive and efficient solutions.

Customized solutions: Houdry's team of engineers understands the material properties and the physical nature of welding, and can customize the optimal welding process solution according to your specific product structure, material properties, performance and appearance requirements, and provide professional consulting support.

One-stop integration advantage: Houdry provides a complete sheet metal manufacturing chain from precision laser cutting/stamping, accurate bending to professional welding, surface treatment and assembly. Choosing Houdry means avoiding the communication costs and quality risks associated with cross-factory collaboration, and enjoying seamless and efficient sheet metal processing services.

At Houdry, we regard every weld as a fulfillment of our promise. Advanced robotic systems are our precise hands, profound process knowledge is our source of wisdom, and the ultimate pursuit of quality is our unchanging faith. We know that a strong welded seam is the starting point of a sheet metal product's vitality.

If you're looking for a sheet metal welding supplier you can trust, feel free to contact the Houdry team. Please provide us with your product drawings or specific requirements, and we will quickly assess the feasibility of your process, develop an optimal solution and provide you with an accurate quote.