Your Trusted Partner for Advanced Sheet Metal Bending Services

In the complex modern manufacturing industry, the perfect combination of form and function requires strict requirements, and precision sheet metal bending is the cornerstone of this process. As a China sheet metal bending services manufacturer, we know that the quality of bending directly affects the integrity, aesthetics and performance of the final product. Houdry specializes in transforming flat metal into complex, dimensionally accurate parts through state-of-the-art sheet metal bending services, providing global customers with trusted reliability, versatility and expertise.

If you are looking for China metal bending services suppliers, choosing Houdry is to choose reliable quality, excellent efficiency and one-stop service! Welcome to inquire!

What is Metal Bending?

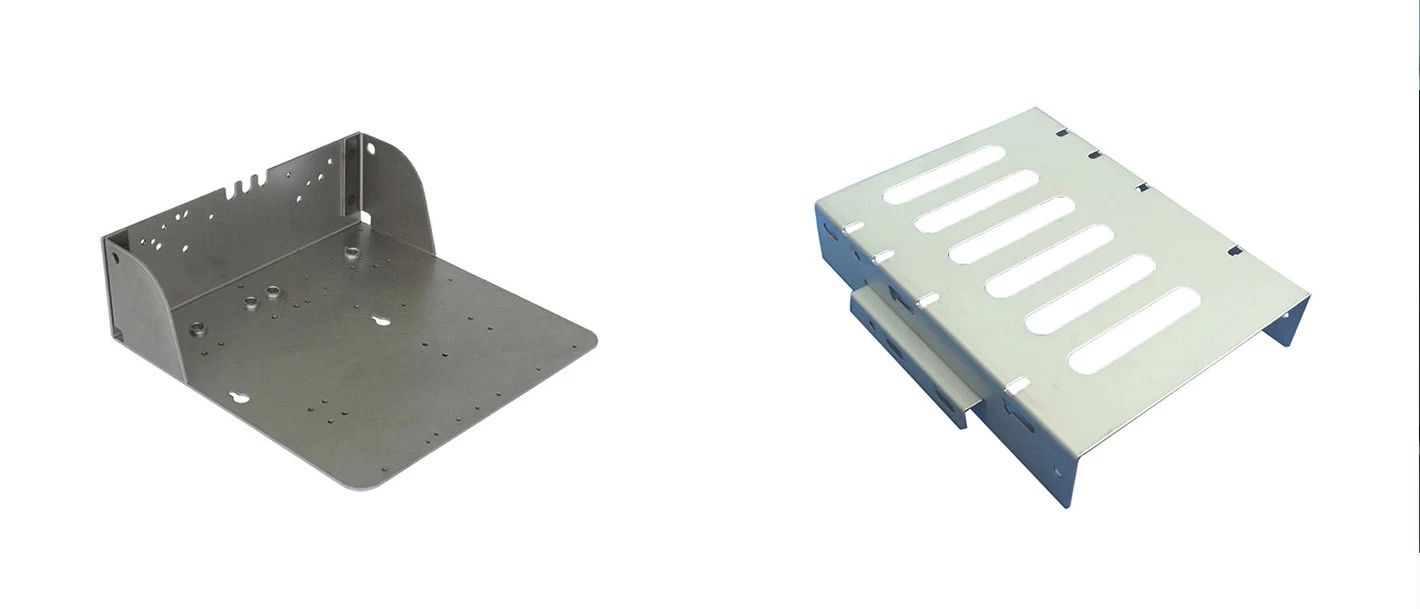

Metal bending is a manufacturing process that applies force to plastically deform metal sheets, bars or tubes along a straight line (bending line) to form specific angles and shapes. Flat metal materials are processed into three-dimensional parts with desired angles (such as 90 degrees, 45 degrees, etc.) or complex contours. China sheet metal bending parts are widely used in the manufacture of various products, such as chassis cabinets, brackets, frames, door panels, housings, pipe components, furniture parts, automotive parts, building components, etc.

The Critical Role of Sheet Metal Bending

Beyond simple metal bending, bending is a complex process that requires a deep understanding of material properties, springback behavior, bend allowances, and tooling interactions. Imprecise bends can lead to assembly issues, structural defects, poor fit, and costly rework. Houdry's CNC sheet metal bending services eliminate these risks. We utilize advanced technology and sophisticated processes to provide bends that meet the tightest tolerances (±0.1 mm or less), ensuring that parts fit perfectly every time, whether it's a precision electronic housing or a rugged structural bracket.

Houdry's Comprehensive Sheet Metal Bending Capabilities

Houdry, as a sheet metal bending service factory in China, has a range of advanced bending technologies to meet a variety of project requirements:

1. Bending Machines (CNC): cnc sheet metal bending is the backbone of our business and Houdry has modern CNC bending machines with high tonnage capacity and long bed lengths using brands such as Amada, Trumpf or Bystronic. Equipped with precision backgauges and state-of-the-art controls, these machines handle complex geometries, multiple bends and high volume production with unrivalled accuracy and repeatability.

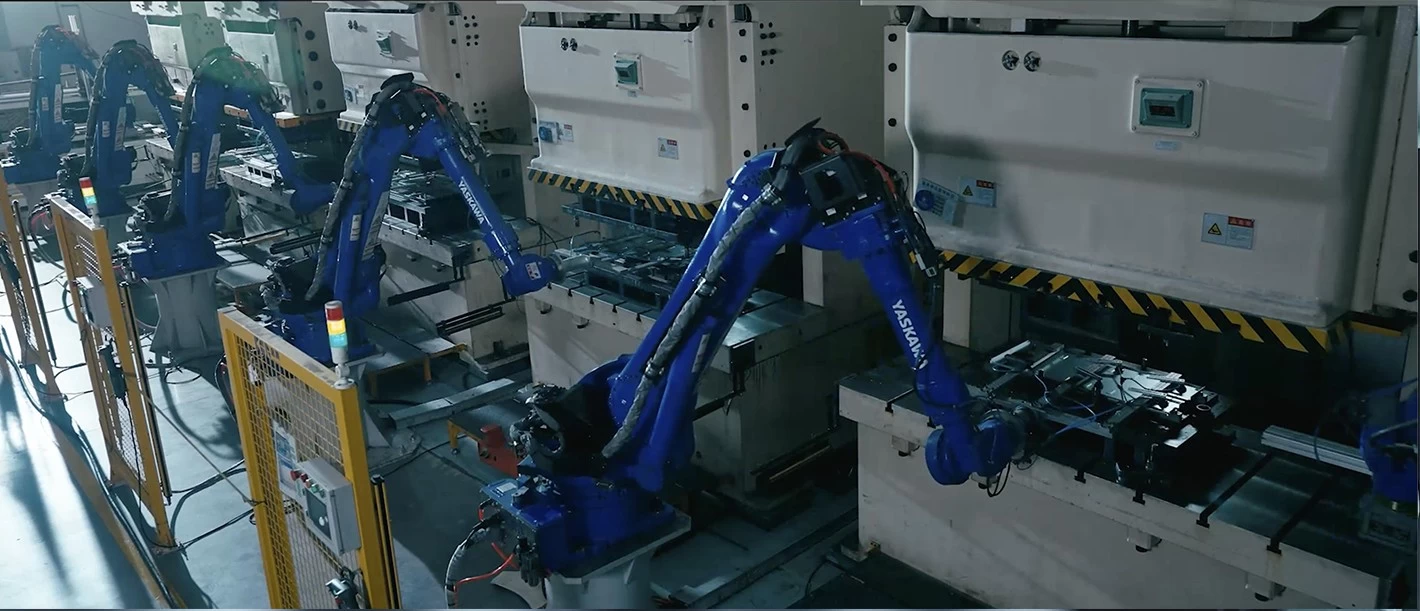

2. Robotic Bending: Houdry's robotic bending cells provide superior speed, consistency, and reduced processing time for ultra-high volume or highly complex parts that require multiple bends to increase productivity.

3. Bending Machines: Ideal for large panels, box forming or applications requiring minimal surface marking. Our panel bending and folding machines provide accurate, high-quality bending of large panels.

4. Specialised bending machines: to meet specific needs such as edge bending, offset bending, tube/profile bending or unique forming requirements.

Houdry's sheet metal bending technology is highly sophisticated and skilled at bending a wide range of plate thicknesses, from ultra-thin gauge to thick plate, for projects that require both delicate detail and ruggedness. Sheet metal bending services are also available for different materials.

Carbon steel: standard tooling for structural components and housings.

Stainless steel: for corrosion-resistant and hygienically demanding applications (food processing, medical, marine). Careful selection of tools and control parameters are required to prevent work hardening or galling.

Aluminium: Lightweight and corrosion resistant, widely used in aerospace, transport and electronics. Attention needs to be paid to springback and potential surface markings.

Copper and brass: Good electrical conductivity and aesthetics, commonly used for electrical components and building elements.

Speciality Alloys: (e.g. Inconel, Titanium - depending on capabilities): High strength or speciality materials treated with special processes.

Applications of Sheet Metal Bending Parts

Our precision sheet metal bending services are fundamental to countless applications:

Electronics & Telecommunications: Enclosures, racks, chassis, heat sinks, brackets.

Industrial Machinery & Automation: Guards, frames, supports, conveyors, panels.

Automotive & Transportation: Brackets, mounts, exhaust components, structural parts.

Medical Equipment: Housings, carts, instrument components, stainless steel assemblies.

Aerospace & Defense: Complex brackets, housings, structural elements .

Renewable Energy: Solar panel frames, inverter housings, mounting structures.

Building & Architecture: Cladding supports, HVAC ducting, decorative elements, fixtures.

Consumer Goods: Appliance panels, housings, frames, retail displays.

Commitment to Quality and Partnership

Quality is embedded in every bend. Our processes adhere to rigorous standards ISO 9001. We employ stringent in-process inspections using calibrated equipment (calipers, height gauges, CMMs, profilometers) to verify angles, dimensions, flatness, and bend positions against your specifications.

As your dedicated sheet metal fabrication manufacturer, we offer more than just bending; we offer a commitment to precision, reliability, and partnership. We understand the critical role accurately bent components play in your product's success. Leverage our advanced technology, extensive material knowledge, deep engineering expertise, and unwavering focus on quality to elevate your next project.

Contact us today to discuss your specific sheet metal bending requirements. We are ready to be your trusted sheet metal bending solution provider.