What Tools are there for Polishing in Sheet Metal Fabrication?

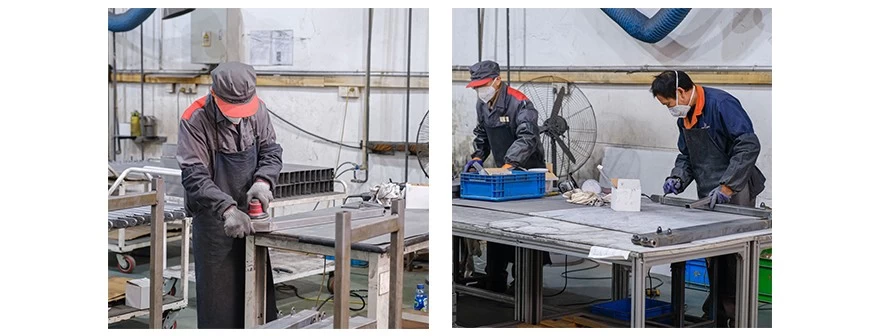

Everyone knows that polishing is an essential process in OEM sheet metal fabrication service. The effect of polishing can not only make the surface of sheet metal parts smoother and burr-free but also increase the adhesion of the coating. If the polishing process is not done well, it will directly affect the appearance of the product, which looks uneven. Therefore, custom sheetmetal fabrication has very high requirements for the polishing process, especially manual polishing. The workers are very experienced technicians. Let me introduce to you what tools are there for polishing sheet metal fabrication?

Angle grinder: Thousand blades or stainless steel bowl brushes can be installed on the tool according to needs; the installation of thousand blades can be used for grinding of welding spatter, grinding of surface bumps and scratches, grinding of welding seam reinforcement, and grinding of processing reinforcement Waiting for work; installing a stainless steel bowl brush can be used for grinding long welds, the main function is to remove the oxide skin in the welding area. There shall be no defects such as cracks, welding tumors, burn-through, arc craters, or trachoma on the surface of the ground weld.

Straight handle grinder: only a special stainless steel bowl brush can be installed on this tool; this tool can only be used for pre-weld grinding of long welds, and the main difference from angle grinders is that this grinder can obtain consistent texture.

Straight grinder: Rotary files, emery cloth wheels, etc. can be installed on the tool according to needs; the installation of cone-headed rotary files can be used for grinding of welded joints, grinding of defects in small spaces, and excessive grinding of deep scratches (depth below 1mm), Residual grinding in narrow spaces, local fine grinding, etc.; installation of emery cloth wheels can be used for grinding and polishing in small spaces that cannot be done by angle grinders, polishing in rounded corners, etc.

Polishing machine: Use a cloth wheel to polish stainless steel products to a shiny surface or polish the welded parts after polishing. Before polishing, the surface of the product needs to be sanded to avoid a matt feeling. After polishing, the welding surface must not have defects such as pores, slag inclusions, arc craters, cracks, arc scratches, and sparking.

Wire-drawing machine: Use a wire-drawing wheel to draw the surface of the stainless steel product or the welding part. After the wire drawing, the surface of the product has the same wire direction and the same thickness. There should be no obvious delamination, blackening and yellowing.