What Should Be Paid Attention to in Stainless Steel Sheet Metal Fabrication?

Stainless steel is a kind of steel that is resistant to weak corrosive media such as air, steam, and water or has stainless properties. It can be often seen in both daily life and industrial applications. Stainless steel is also often used in sheet metal fabrication, the methods of stainless steel sheet metal fabrication include laser, CNC punching machine, shearing plate, mold, etc. So what should be paid attention to in stainless steel sheet metal fabrication?

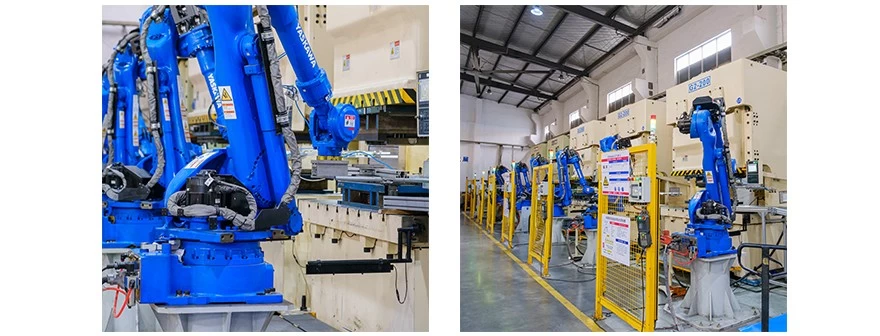

The sheet metal industry is developing rapidly, now sheet metal involves all walks of life. Any sheet metal part has a certain processing process, There are clear regulations on the division of labor and operation of stainless steel sheet metal fabrication, according to the number of products and Shapes choose different blanking methods.

1. High cutting force and high cutting temperature

This type of material has high strength, large tangential stress, and large plastic deformation during cutting, so the cutting force is large. In addition, the thermal conductivity of the material is extremely poor, which causes the cutting temperature of stainless steel to rise, and the high temperature is often concentrated in the narrow and long areas near the cutting edge, thereby accelerating the wear of the cutting tool.

2. Severe work hardening

Stainless steel and some high-temperature alloy stainless steels are austenitic and have a large tendency to work hardening during cutting, which is usually several times that of ordinary carbon steel. The cutting tool is cut in the work hardening area, which shortens the tool's life.

3. Easy to stick to the knife

Both austenitic stainless steel and martensitic stainless steel have the characteristics of strong chips and high cutting temperatures during processing. When the tough chips flow through the rake face, sticking phenomena such as bonding and welding will occur, which will affect the surface roughness of sheet metal fabrication parts.

4. Accelerated tool wear

The above-mentioned materials generally contain elements with high melting points, high plasticity, and high cutting temperature, which accelerates tool wear, frequent tool sharpening, and tool replacement, which affects production efficiency and increases tool cost. The thermal conductivity of stainless steel is relatively poor, and it is difficult to drill holes, so it is necessary to select suitable tool materials.

After the stainless steel products are processed and shaped, sometimes surface treatment is required, such as electroplating, sandblasting, shot blasting, baking paint, anti-fingerprint treatment, etc. The surface treatment of stainless steel can not only improve the aesthetics of the product but also further enhance the corrosion resistance, durability, and wear resistance of stainless steel products.