How to reduce noise of sheet metal processing workshop

Angelina Dong

original

2015-10-22 10:45:42

Angelina Dong Email: sales3@sheetmetal-fabrication.com

In sheet metal processing, inevitably will produce noise, how to make Sheet metal processingThe noise reducing?1, ventilation treatment: because the heat generated by the operation sheet metal processing equipment itself, combined with the glass wool sound-absorbing materials has the thermal insulation properties, internal production line in a closed after 3 ~ 5 ℃ temperature are often higher than the outside.In the implementation of noise control engineering, are typically installed at the top of the sound barriers exhauster, draining closed the hot air inside the space, to form internal negative pressure, outside air by sound barriers into the internal.In selecting convulsions machine with low noise fan so as not to affect the effect of noise reduction.

2, workshop reverberation time and noise noise: to determinate the reverberation time is refers to the interior sound reached a stable state, residual sound source stops after the voice to and fro in the room reflected by the surface absorption, the average sound energy density reduced to one over one million of the original value of the time.

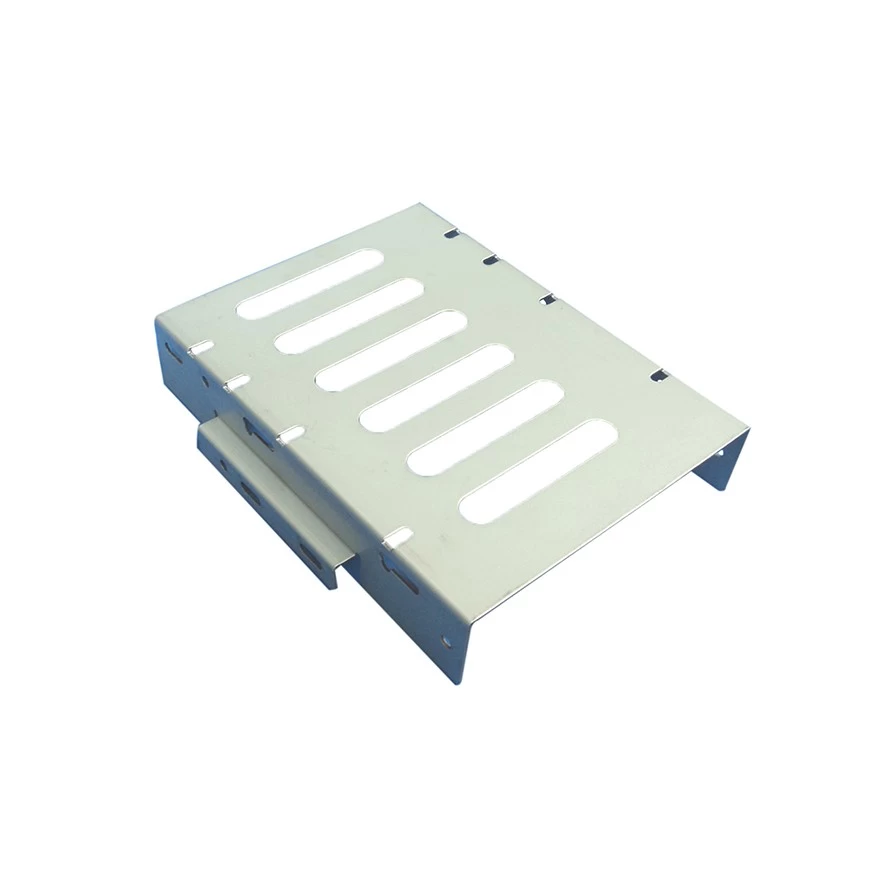

3, sound-absorbing materials choice: sound insulation board of five parts, the noise through perforations holes into the sound-absorbing cotton, part through glass cotton silk vibration energy into heat energy consume, isolated from the other part is the outer plate, achieve the goal of every common absorption.

(1) the outer layer of the thickness of 2 mm steel plate, sound insulation and support role, and the surface is sound-absorbing board.

(2) the sound-absorbing board in the middle part as the sound-absorbing material, material for glass cotton products, used to absorb sound energy, is a major component of the noise reduction materials.

(3) fiber board pasted outside the sound-absorbing cotton, to prevent falling sound-absorbing cotton.

(4) through the sound film on both sides of the sound-absorbing cotton, moistureproof and prevent the sound-absorbing cotton silk fall off from the mesh of the inner perforated plate.

4, sound-absorbing board sealing treatment: because of the sheet metal processing production line closed treatment is the multiple small sound-absorbing board of joining together into a closed body, so in order to ensure that the noise reduction effect, good in design and manufacture of the need to control the clearance between the sound-absorbing board.

5, lighting processing: due to closed the project after the separate equipment inside and outside the workshop lighting, so closed need to increase the lighting system in the body.Late in order to ensure the production and maintenance needs of lighting, illumination design reaches more than 500 lumens.Closed lighting system in the body to separate wiring, independent switch, ensure ease of use and does not affect the original power supply system.All of a sudden power failure, in addition, in order to prevent the workshop equipped with emergency lighting in a closed system to ensure the safety of equipment and personnel.

When we were in sheet metal processing and security is first, is engaged inSheet metal processingWorkers must keep in mind.