- Contact Us

-

Contact: Devin Liu

E-mail: sales@sheetmetal-fabrication.com

Tel: +86 13382165719

Wechat: LGQ4169719 Contact Now

Contact Now

- New Products

- Latest News

-

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the custom design and fabrication of stainless steel, iron, aluminum, galvanized sheet and other materials. The fabricatio...what is advantage of anodic oxidation and anodized ?

Anodizing (spelled anodizing, in Singapore, the UK, India, and Australia) is an electrolytic passivation process used to increase the thickness of the...China Internation Furniture Fair 2017

From September 11 to 14, 2017, the 40th CIFF Shanghai will present a fantastic feast for the furniture and home furnishings industry. CIFF features th...How coronavirus impact global economy?

The coronavirus outbreak, which originated in China, has infected more than 200,000 people. Its spread has left businesses around the world counting c...

- Subscribe

-

Get email updates on new products

China Welding Sheet Metal Fabrication Manufacturer

- Place of Origin: Jiangsu, China (Mainland)

- Brand Name: HOUDRY

- Model Number: Custom Made

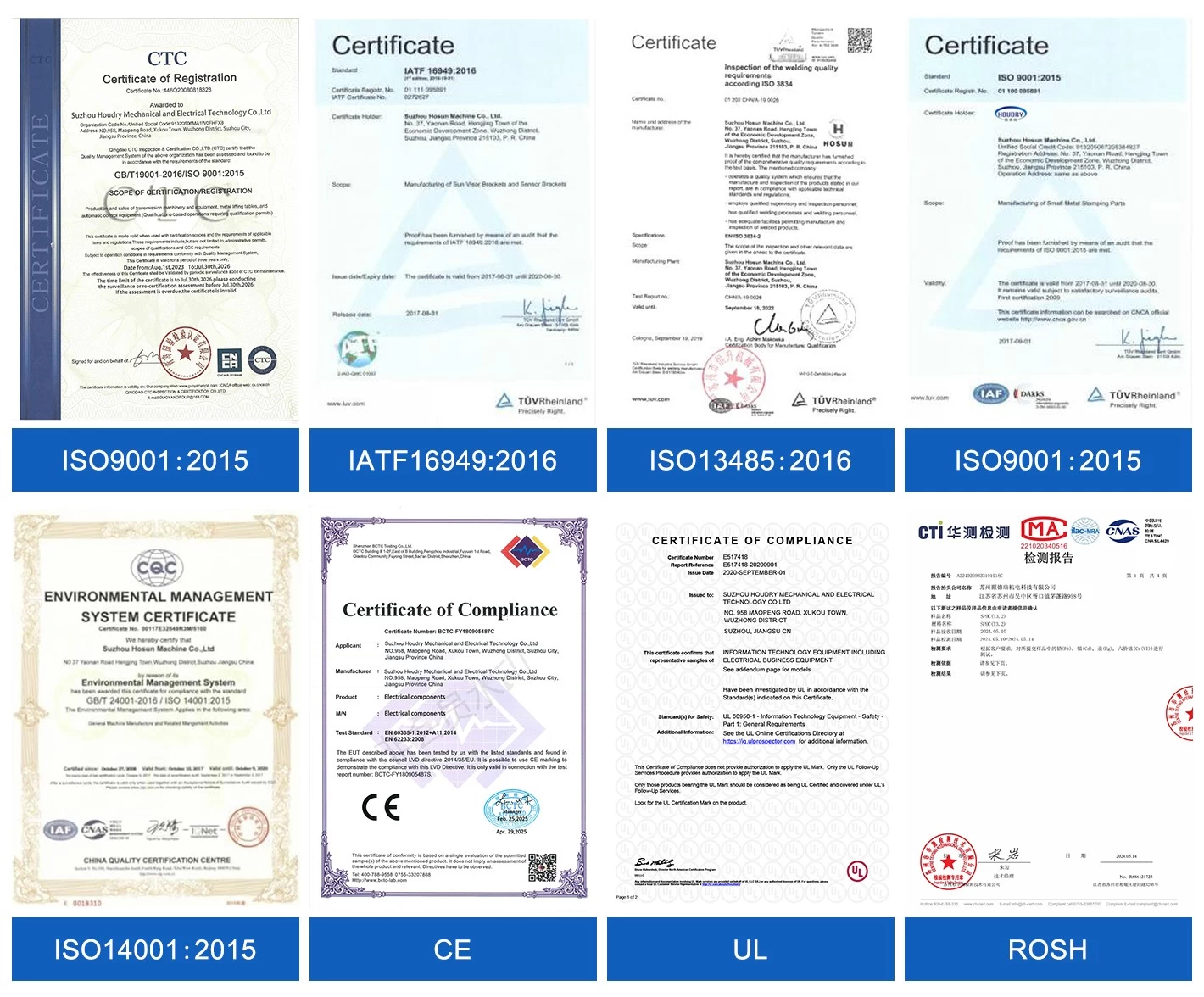

- Certificate: ISO9001:2015/SGS

- Material: Stainless Steel/Iron/Aluminum

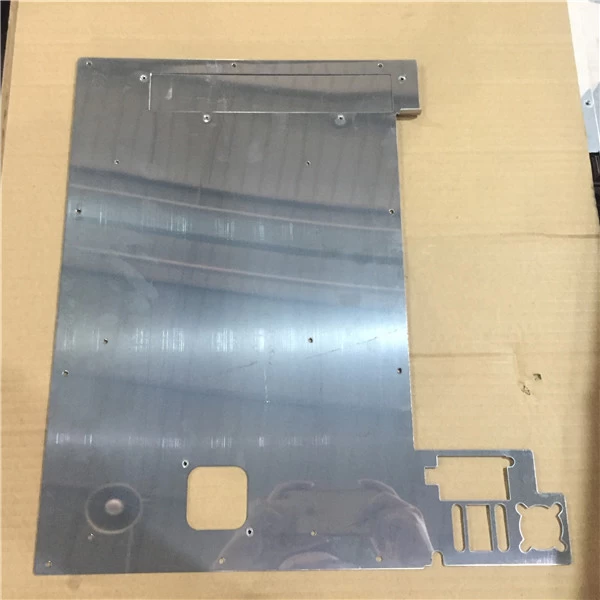

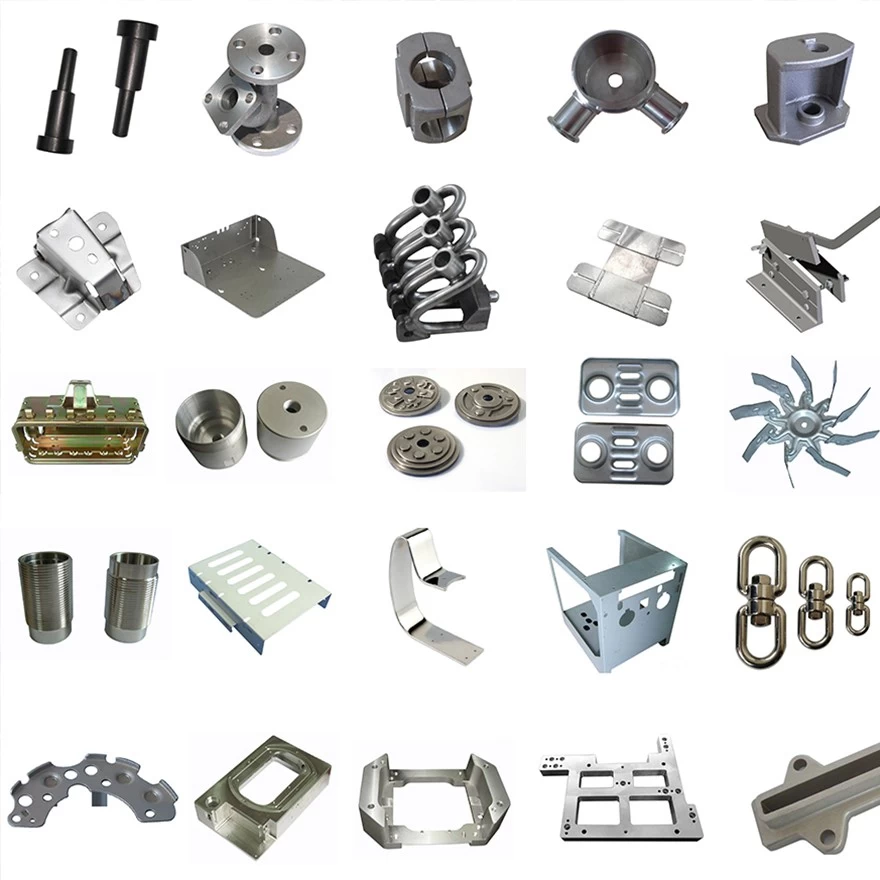

- Fabrication Process: Stamping, Bending, Laser Cutting, Welding, Forging, Casting, Maching and so on.

- Tolerance: ±0.1mm

- Surface Treatment: Mirror Polishing, Powder Coat, Zinc Plate, Paint, Brushing as per drawing.

- Service: Custom OEM/ODM sheetmetal fabrication service

- Supplier Type: Manufacturer/Fabcicator/Factory/Designer

- Package: Standard package/individual package for export or as requested.

- Delivery time: 7 - 20 working days or negotiable

| Description |

Competition among China welding sheet metal fabrication manufacturer is fierce, and this isn't just a local phenomenon; it's a typical feature of a global industrial restructuring.

Over 95% of Chinese sheet metal fabrication manufacturers are small and medium-sized, relying on price wars to secure orders. This results in very low profit margins, with many even accepting orders at near-zero profit margins to maintain normal operations. This phenomenon isn't limited to China sheet metal welding services; similar situations exist across many industries.

As a small and medium-sized sheet metal fabrication manufacturer in China, Houdry saw its order volume decline significantly amid the economic downturn of 2025. We are grateful to our long-standing customers for their continued support.

In response to this phenomenon, Houdry is also adapting, such as expanding its product offerings:

Sheet metal for energy equipment; providing one-stop "cutting + bending + welding" solutions to expand our customer base; and renting expensive fiber laser cutting machines to meet customer processing needs at a lower cost. China sheet metal fabrication and welding offers many advantages. We accept small orders and are responsible for customer certification. If you're also looking for a sheet metal fabrication manufacturer, please contact us!

| Specifications |

| Place of Origin | Jiangsu, China (Mainland) |

| Brand Name | HOUDRY |

| Model Number | Custom Made |

| Certificate | ISO9001:2015/SGS |

| Material | Stainless Steel/Iron/Aluminum |

| Fabrication Process | Stamping, Bending, Laser Cutting, Welding, Forging, Casting, Maching |

| Tolerance | ±0.1mm |

| Surface Treatment | Mirror Polishing, Powder Coat, Zinc Plate, Paint, Brushing as per drawing |

| Service | Custom OEM/ODM sheetmetal fabrication service |

| Supplier Type | Manufacturer/Fabcicator/Factory/Designer |

| Package | Standard package/individual package for export or as requested |

| Delivery time | 7 - 20 working days or negotiable |

| More Products |

| Company Introduction |

Welcome to Houdry! We are a professional China sheet metal fabrication supplier. The factory is located in Suzhou, China, covering an area of 50,000 square meters. We currently have four professional sheet metal manufacturing centers and a professional R&D base. The business scope is mainly precision molds, laser cutting, stamping, machining, bending, welding, spraying and other manufacturing processes.

Since its establishment in 2008, the founder started a hard business with one machine and one worker. After nearly 20 years of unremitting efforts, the company currently has a total of 405 employees, including 30 R&D engineers, 25 process engineers and 8 quality engineers.

Houdry has always been committed to providing customers with high-quality, high-precision and high-efficiency sheet metal processing service solutions to meet all-round needs from prototype development to mass production. At present, Houdry customers are spread across more than 30 countries around the world, and its products cover home appliances, furniture, medical, automotive and new energy fields.

| Certificate |

As a China stainless steel sheetmetal fabrication supplier, Houdry is well aware that excellent quality, rigorous process and responsibility for the environment and safety are the core of sustainable development.

The following are the main international certifications and recognitions we have obtained:

| Equipment |

We have laser cutting machine, robot wenlding machine, bending machine, stamping machine, cnc machining centers, milling machine, grinding machine, injecton mold machine and so on equipments. Can produce most metal products.

| Testing equipment |

| Package and Shipping |

Standard package/individual package for export or as requested. Sheet metal parts are usually packed in carton box, then packed in plywood pallets or plywood boxes.

| FAQ |

1. What is your typical lead time for sheet metal fabrication projects?

Standard lead times range from 5–15 business days after design approval, depending on project complexity, material availability, and order volume. Rush services may be available for urgent requests—contact our team for expedited options.

2. What materials do you work with for sheet metal fabrication?

We process a wide range of materials, including:• Mild Steel • Stainless Steel (304/316) • Aluminum (5052, 6061) • Copper • Brass • Galvanized SteelCustom material requests can be accommodated—inquire for specific alloys or thicknesses.

3. What file formats do you accept for part design?

We prefer industry-standard formats for seamless processing:• Preferred: .STEP, .IGES, .DXF/DWG (2D drawings)• Accepted: .SLDPRT, .PDF (with dimensions)Design support (DFM feedback) is available upon request to optimize manufacturability.

4. How do you ensure quality control in your fabrication process?

All parts undergo rigorous quality checks, including:• In-process inspections • Dimensional verification (with CMM/laser scanning) • Surface finish review • Final compliance with ISO 9001 standardsCertified material test reports (MTRs) and inspection documentation are provided upon request.

5. Do you offer design for manufacturability (DFM) feedback?

Yes! We provide complimentary DFM analysis to reduce costs, improve functionality, and streamline production. Share your design files with our engineering team for actionable recommendations on material selection, tolerances, bend radii, and efficiency optimizations.

Tel:8613382165719

Wechat:LGQ4169719

Facebook:ahlgq2000@163.com

Contact Person:Devin Liu

PDF Show:PDF