What are the characteristics of sheet metal fabrication?

Sheet metal technicians need to master the technology of sheet metal fabrication, which is an important process for forming a high-quality, high-static sheet metal fabrication parts wholesale. So what are the characteristics of sheet metal fabrication technology? Let me introduce to you.

1. High power density of sheet metal fabrication: The workpiece absorbs the rapidly rising temperature after sheet metal fabrication and melts or vaporizes, even materials with high melting point, high hardness and high brittleness (such as ceramics, diamond, etc.).

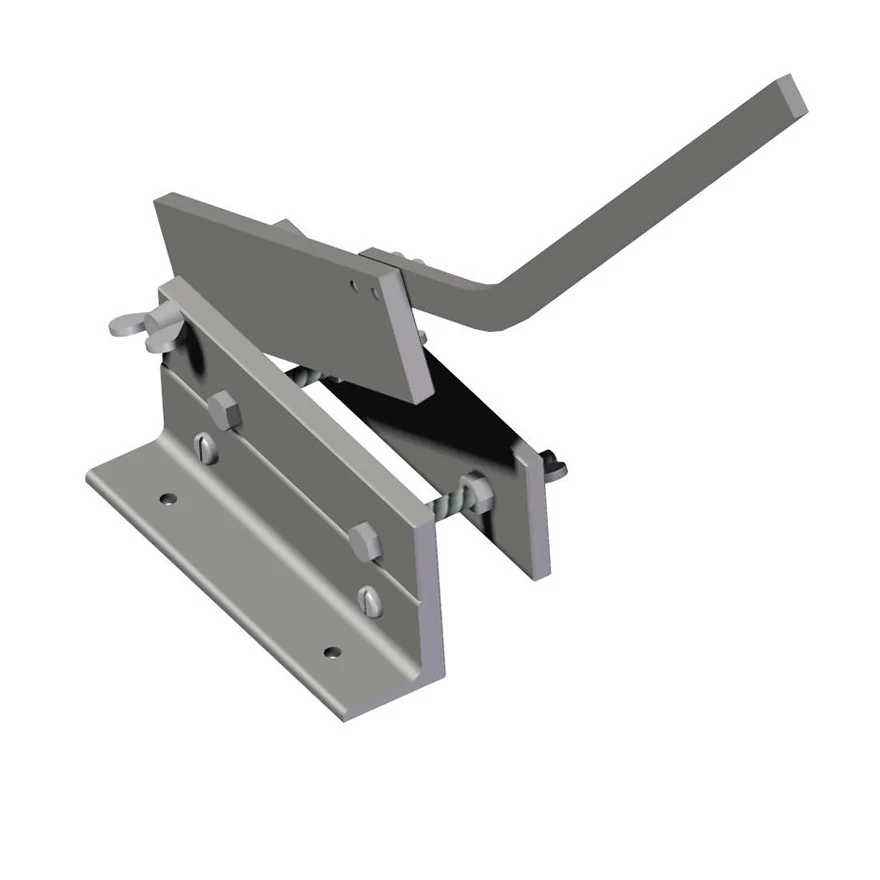

2. The plate processing beam is easy to control: it is easy to combine with precision machinery, precision measurement technology, electronic computer, etc. to achieve high precision and high automation.

3. Convenient and flexible sheet metal fabrication: robots can process sheet metal in harsh environments or in places that are inaccessible to others.

4. Sheet metal machining is widely used: the divergence angle of the sheet metal machining beam can be less than 1mm arc, the spot diameter can be less than microns, and the working time can be as short as nanoseconds and picoseconds. At the same time, the continuous output power of high-power plate processing can reach the kilowatt level to ten kilowatt level. According to the characteristics of the welding process, three welding methods are used in industrial production.

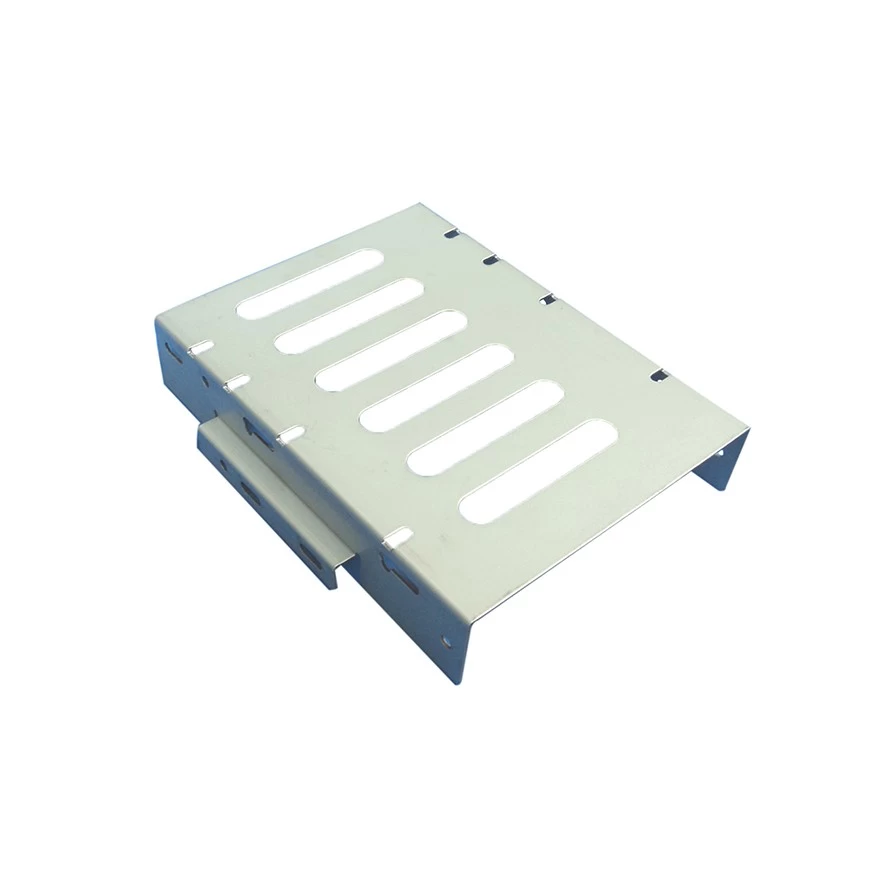

5. Compared with the production and processing of forgings and castings, sheet metal parts have the advantages of light weight, saving metal materials, simple processing technology, reducing production costs, and saving production costs.

6. Most welded sheet metal parts have low machining accuracy and large welding deformation, so the deformation and correction after welding are large.

7. Since the welded parts are non-removable and difficult to repair, reasonable assembly methods and procedures are required to reduce or avoid scrap. Large or oversized products often require on-site assembly, so trial assembly should be done at the factory first. During trial assembly, non-removable connections shall be temporarily replaced with removable connections.