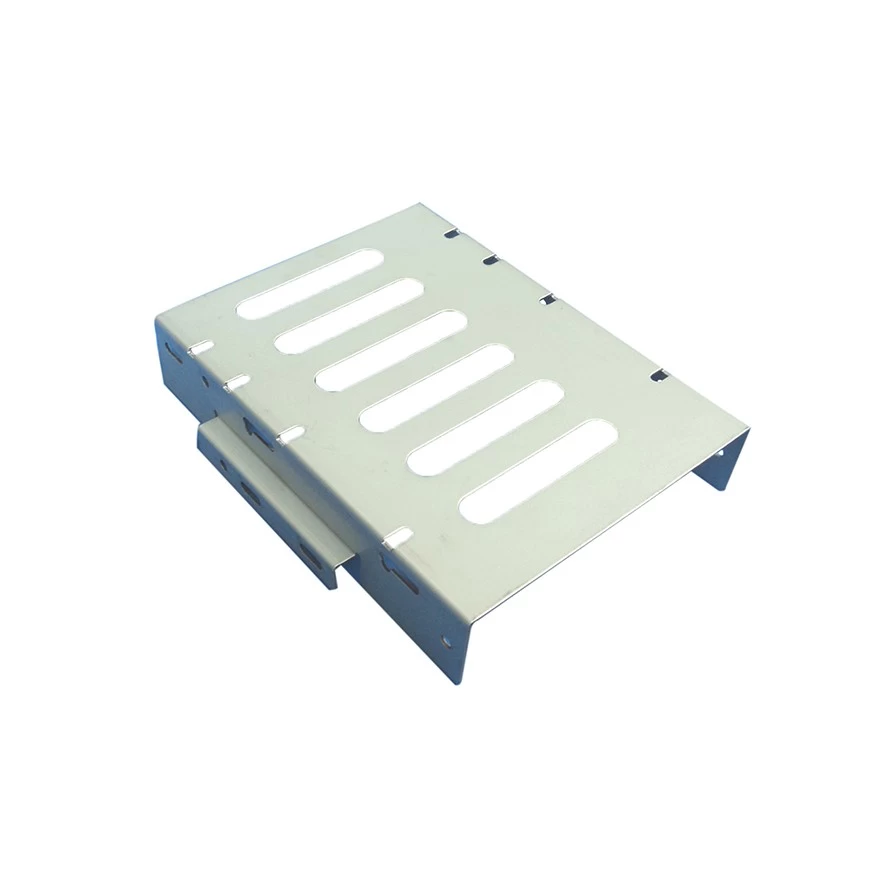

Improve the Efficiency and Quality of Sheet Metal case Fabrication

Powder coating is a surface treatment technology widely used in the field of sheet metal fabrication, especially in the manufacture of metal casings. Powder coating is achieved by electrostatically spraying dry powder onto the metal surface and then curing it at high temperature to form a durable and beautiful coating. This process not only improves the corrosion resistance and wear resistance of the product, but also has the advantages of being environmentally friendly and cost-effective.

Powder coating is often applied as the last step in the China sheet metal case fabrication manufacturer process. For example, when manufacturing household appliances, automotive parts, or mechanical equipment housings, powder coating can provide a variety of colors and decorative effects while enhancing the product's durability and impact resistance. Powder coatings come in two types: thermoplastic and thermosetting, each with its own unique application scenarios and advantages.

The process of powder coating generally includes the following steps: first, pretreatment to ensure that the metal surface is clean and grease-free; then spraying, using high-voltage static electricity to evenly apply the powder to the metal surface; followed by curing, heating to melt the powder and form a solid coating.

China powder coating sheet metal case fabrication is widely used, not only for commercial projects, but also for various industrial equipment and household appliances. It can provide excellent adhesion and durability while reducing waste and environmental impact, and is an efficient and economical surface treatment method.

To improve the efficiency and quality of sheet metal case fabrication China supplier , we can start from the following aspects:

1. Adopt lean manufacturing principles: Lean manufacturing is a method that aims to optimize resource management (such as materials, energy and labor) to reduce waste and improve production efficiency. By implementing lean principles, an efficient production process can be created, thereby improving the overall efficiency of sheet metal case processing.

2. Optimize design and manufacturing processes: During the design phase, following the principles of design feasibility (DFM) can significantly improve production efficiency. For example, simplifying the design, reducing complexity, and rationally selecting materials and tolerances can reduce production costs and shorten production cycles. In addition, optimizing the design using modern design software and simulation tools can further improve manufacturing efficiency.

3. Use advanced technology and equipment: Advanced technologies such as CNC machines and 3D printing can improve processing accuracy and speed. These technologies are able to handle complex shapes and details while reducing material waste, thereby improving product quality.

4. Strict quality control: Implement strict quality control measures during the production process, including inspection, testing, and documentation, to ensure that the quality and performance of the final product meet standards. Choosing a manufacturer with a good reputation and certification is also an important means of ensuring quality.

5. Optimize material selection and process flow: Select materials that are suitable for application requirements, and balance processes such as cutting methods, bending techniques, welding methods, and prototyping according to project requirements.

In addition, production efficiency can be further improved by optimizing equipment configuration and employee training.