China Sheet Metal Custom Fabrication Manufacturing Technology and Process

China sheet metal custom fabrication manufacturer has significant development and advantages. Sheet metal processing is a subtractive manufacturing process that makes parts by cutting metal sheets. It is widely used in various industries, including electricity, network communications, home appliances, architectural decoration, etc.

China supplier sheet metal custom fabrication has been widely used and developed. For example, laser cutting technology has become one of the important means of sheet metal processing, and many companies provide high-power laser cutting services, which can efficiently process various metal sheets. In addition, sheet metal processing also involves complex processes such as bending and forming, which can be assisted by robots to achieve high-precision and high-flexibility production.

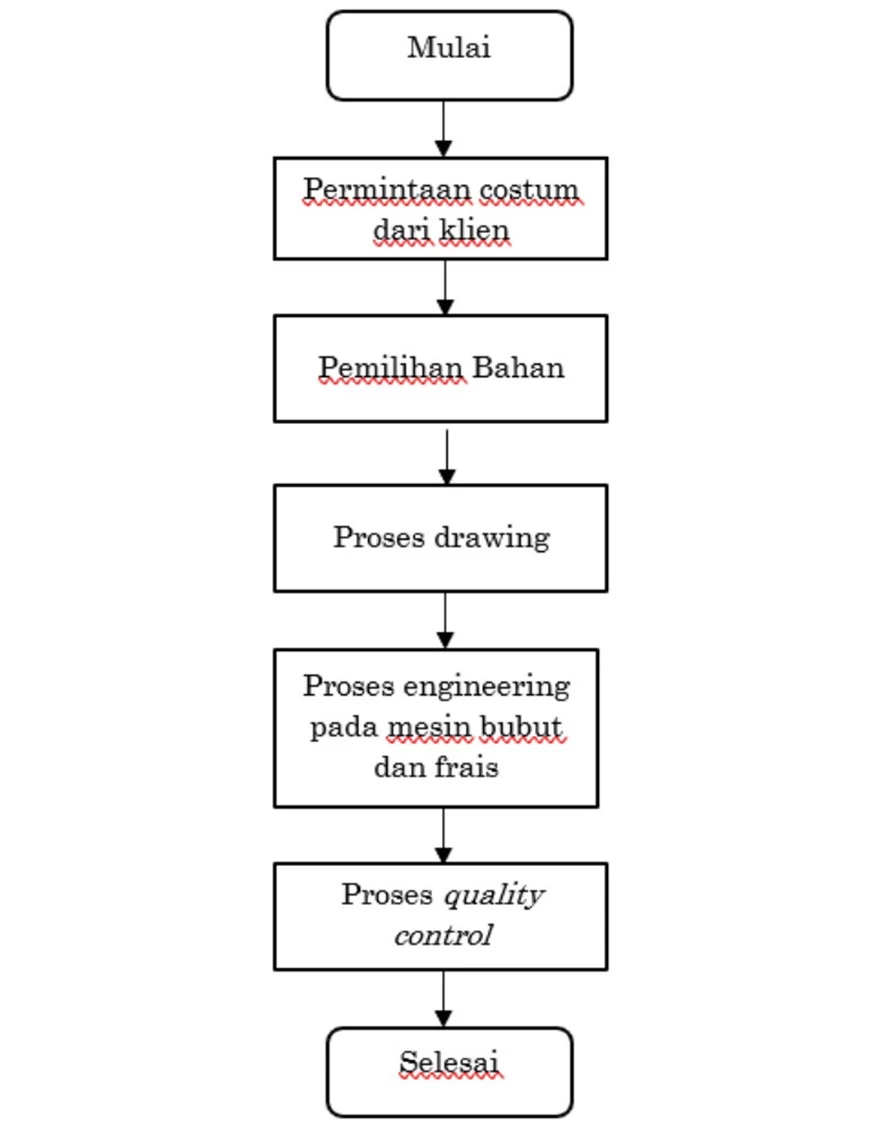

1. Customer order: First, determine the specific specifications and requirements of the required sheet metal parts according to the customer's order requirements

2. Material selection: Select the appropriate material according to the order requirements. Commonly used materials include stainless steel, aluminum, copper and other metal materials, which have different physical and chemical properties and are suitable for different application scenarios.

3. Drawing production: Make detailed engineering drawings or designs based on customer needs and selected materials. This step is the basis of the entire production process and ensures the accuracy and consistency of subsequent processing.

4. Cutting: Cut the selected materials according to the drawing requirements. This step may involve technologies such as laser cutting and CNC cutting to ensure cutting accuracy.

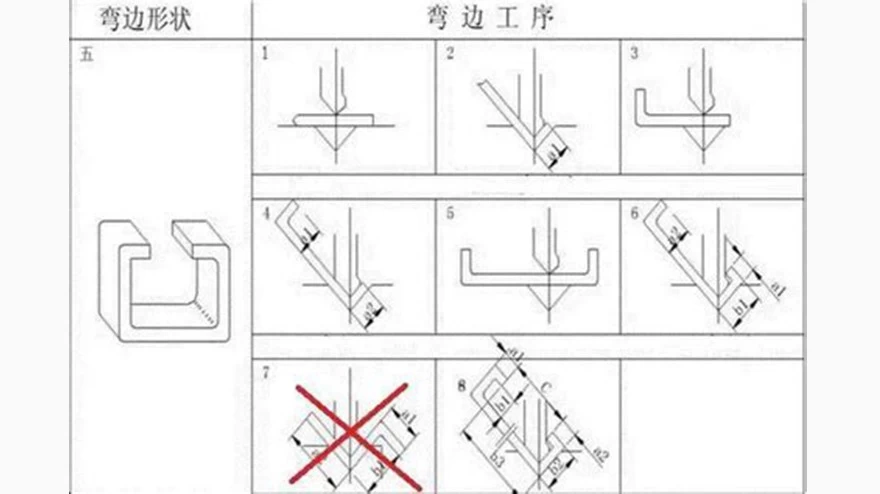

5. Bending and forming: The cut sheets are bent and formed by bending machines or other forming equipment. This step is a very critical link in sheet metal processing and determines the shape and size of the final product.

6. Welding and assembly: For complex products that require multiple parts, welding and assembly are performed. This step may include techniques such as spot welding and seam welding to ensure a strong connection between the components.

7. Surface treatment: According to the requirements of the product, surface treatment such as painting, electroplating, anodizing, etc. can be carried out. These treatments can improve the corrosion resistance, aesthetics and service life of the product.

8. Inspection and quality control: After each production stage, the product needs to be inspected to ensure that it meets the design requirements and quality standards. This includes size inspection, surface inspection, etc.

9. Packaging and delivery: Finally, the finished product is packaged and shipped according to customer requirements. This step ensures that the product can be delivered to the customer safely and promptly.

The above are the main production processes and procedures of China sheet metal custom fabrication factory. Each step requires strict quality control and process optimization to ensure the high quality and high performance of the final product. China sheet metal custom fabrication industry not only has advantages in traditional processes, but also continues to introduce new technologies and processes to meet the needs of different customers. Whether it is small batch produ