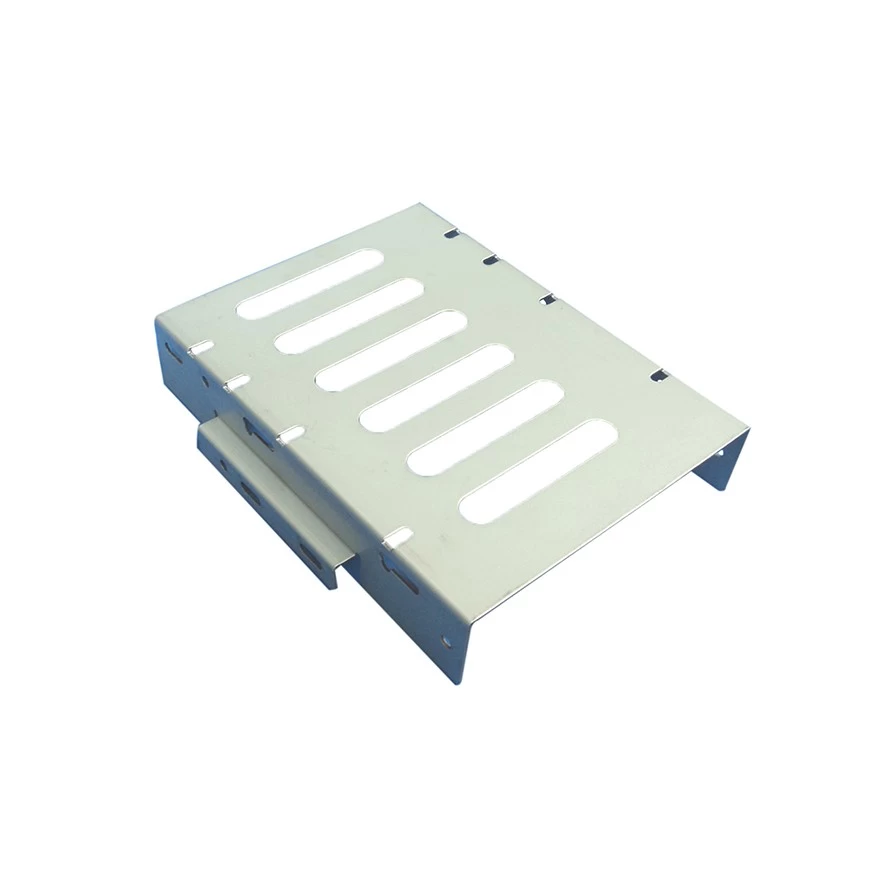

sheet metal bending skills

Yummy Yao

2015-07-15 14:00:32

Bending of material, on its rounded corners, outer received stretching, the inner layer is compressed. When the material thickness is constant, the smaller r, the amount of stretching and compression of the material is more severe; when the outer corners of the tensile stress over when the ultimate strength of the material, it will crack and break, therefore, the structural design of bending part, avoid small bending radii. The technological requirements to note each of these processes. Is the bending standards outlined below.

The minimum bending radii, bending bending of material, on its rounded corners, outer received stretching, the inner layer is compressed. When the material thickness is constant, the smaller r, tensile and compression of the material the more serious when the outer corners of the tensile stress over when the ultimate strength of the material, it will crack and break, therefore, the structural design of bending part, avoid small bending radii.

Second, bending straight edge height minimum height under normal circumstances requires, bending the straight side height should not be too small, minimum height requirements: h>2T.

Three, and special requirements of straight side height if design need bent pieces of straight side height h<2t,, is first to increased bent side height, bent good hou again processing to need size; or in bent deformation district within processing shallow slot hou, again folding curved side side side with bevel of straight side height four, and dang bent side side side with bevel of bent pieces shi, side of minimum height for: h= (2~4) t>3mm; folding bent pieces Shang of hole side from, hole side from: first punching Hou folding bent, hole of location should in bent deformation district outside, To avoid bending hole will produce distortion.

Four bending process, local incisions six, bending the curve should avoid sudden change of local bending a edge, crack produces bending stresses set in order to prevent sharp corners, curved lines can be moved a certain distance, mutation or to leave the dimension began art grooves, or punching hole. Note the size requirements: S≥R; width of Groove KT; the depth Lt+R+k/2. When the hole is bent in the deformation zone, take the form of cuts when the hole is bending deformation zone, cut form.

Five, bend with a bevel edge should be avoid deformation design requirement of eight killed killed dead side of the edge length and the thickness of the material. General death minimum edge length L≥3.5t+R. Where t is the wall thickness of the material, r for killing the former procedure the minimum bend RADIUS. Six design process on them when locating holes in order to ensure accurate positioning in the rough in the mold to prevent bending stock offset Continu, should be added at design time in advance process of positioning hole, as shown in the following figure. Especially the repeated bending of parts, must be the technological holes for positioning the benchmark to reduce errors, ensure the quality of products.

Seven bent, mark related dimensions, taking into account the technology of high precision, you need to first after bending processing, processing problems third, rebound effects of bending rebound of many factors, including: the mechanical properties of the material, wall thickness and bending radius and bending stress.

The minimum bending radii, bending bending of material, on its rounded corners, outer received stretching, the inner layer is compressed. When the material thickness is constant, the smaller r, tensile and compression of the material the more serious when the outer corners of the tensile stress over when the ultimate strength of the material, it will crack and break, therefore, the structural design of bending part, avoid small bending radii.

Second, bending straight edge height minimum height under normal circumstances requires, bending the straight side height should not be too small, minimum height requirements: h>2T.

Three, and special requirements of straight side height if design need bent pieces of straight side height h<2t,, is first to increased bent side height, bent good hou again processing to need size; or in bent deformation district within processing shallow slot hou, again folding curved side side side with bevel of straight side height four, and dang bent side side side with bevel of bent pieces shi, side of minimum height for: h= (2~4) t>3mm; folding bent pieces Shang of hole side from, hole side from: first punching Hou folding bent, hole of location should in bent deformation district outside, To avoid bending hole will produce distortion.

Four bending process, local incisions six, bending the curve should avoid sudden change of local bending a edge, crack produces bending stresses set in order to prevent sharp corners, curved lines can be moved a certain distance, mutation or to leave the dimension began art grooves, or punching hole. Note the size requirements: S≥R; width of Groove KT; the depth Lt+R+k/2. When the hole is bent in the deformation zone, take the form of cuts when the hole is bending deformation zone, cut form.

Five, bend with a bevel edge should be avoid deformation design requirement of eight killed killed dead side of the edge length and the thickness of the material. General death minimum edge length L≥3.5t+R. Where t is the wall thickness of the material, r for killing the former procedure the minimum bend RADIUS. Six design process on them when locating holes in order to ensure accurate positioning in the rough in the mold to prevent bending stock offset Continu, should be added at design time in advance process of positioning hole, as shown in the following figure. Especially the repeated bending of parts, must be the technological holes for positioning the benchmark to reduce errors, ensure the quality of products.

Seven bent, mark related dimensions, taking into account the technology of high precision, you need to first after bending processing, processing problems third, rebound effects of bending rebound of many factors, including: the mechanical properties of the material, wall thickness and bending radius and bending stress.