The precision of laser cutting processing products to further improve

Angelina Dong

Original

2015-07-13 17:49:00

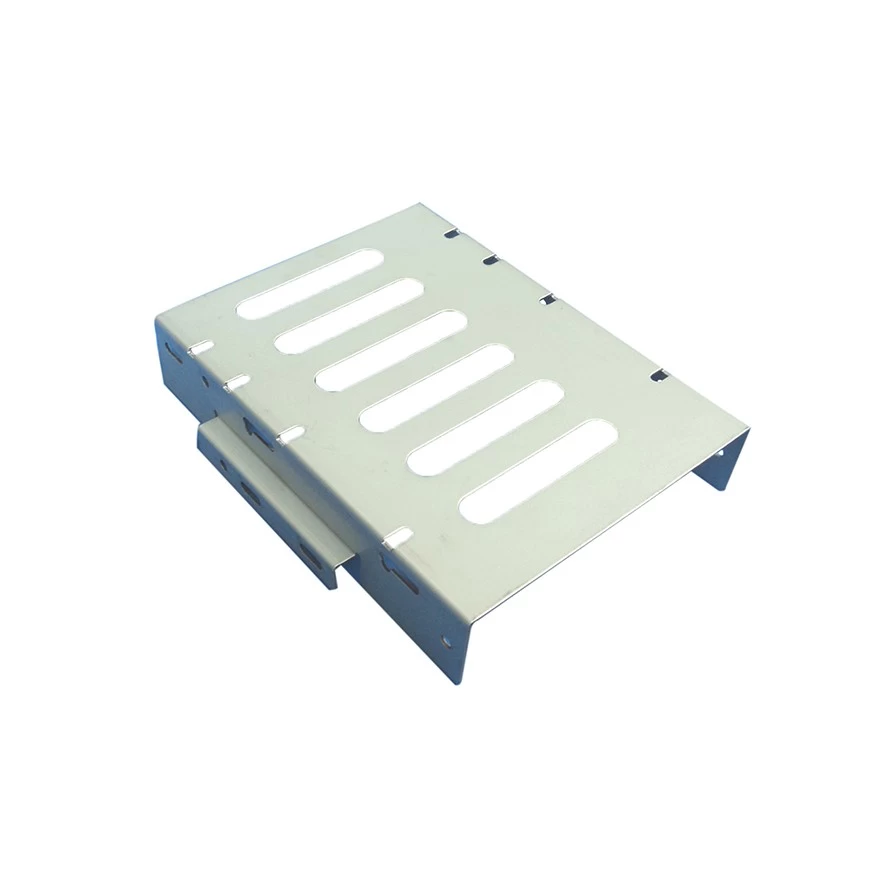

Due to the laser cutting processing speed is improved, and machining of prompting the range of thermal effect gradually decreases, and the whole work in cutting processing of thermal deformation is reduced.At the same time, due to carbon dioxidelaserThe stability of the gradually improve, also prompted laser cutting surface roughness increases.In addition, greatly reducing the vibration and machining the stillness of the way.Due to the precision of laser cutting processing level enhances unceasingly, makes the laser cutting processing of farm machinery sheet metal parts also gradually changed, from the original low precision turning to high precision parts.From the point of practical production situation, the original composite machine APELIO Ⅱ 357 is usually processed material thickness less than 2 mm thinner parts, main processing is outside the tolerance of textile machinery.Now laser cutting machine can process the parts above, also can processing material thickness to 3 mm, 4 mm or greater than 6 mm thick parts.Such parts mostly structure, transmission as well as the main working parts, for processing precision demand is higher, among them, some of the precision of parts is close to the job requirements.With laser cutting processing parts, not only has the characteristics of small deformation, the machined surface finish high, as well as small process burrs doesn't even have a good consistency, the size of the parts, in the agricultural machinery assembling dimensional precision control has the biggest role.