- Contact Us

-

Contact: Devin Liu

E-mail: sales@sheetmetal-fabrication.com

Tel: +86 13382165719

Wechat: LGQ4169719 Contact Now

Contact Now

- New Products

- Latest News

-

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the custom design and fabrication of stainless steel, iron, aluminum, galvanized sheet and other materials. The fabricatio...what is advantage of anodic oxidation and anodized ?

Anodizing (spelled anodizing, in Singapore, the UK, India, and Australia) is an electrolytic passivation process used to increase the thickness of the...China Internation Furniture Fair 2017

From September 11 to 14, 2017, the 40th CIFF Shanghai will present a fantastic feast for the furniture and home furnishings industry. CIFF features th...How coronavirus impact global economy?

The coronavirus outbreak, which originated in China, has infected more than 200,000 people. Its spread has left businesses around the world counting c...

- Subscribe

-

Get email updates on new products

Category

-

-

China Custom Sheet Metal Fabrication Services Machined Aluminum Parts

As a leading China OEM Metal Fabrication expert, we offer unparalleled expertise in transforming raw materials into complex, high-tolerance components.

More

-

-

China Air Conditioning Sheet Metal Manufacturer OEM Metal Fabrication

As a pioneering force in this field, we - experts in sheet metal fabrication for dozens of years - with China Precision Sheet Metal Fabrication as the cornerstone, are committed to transforming precision craftsmanship into We are committed to transforming precision workmanship into reliable skeletons and precision housings for air-conditioning equipment.

More

-

-

Custom Shell Processing Sheet Metal Fabrication for the Aerospace Industry

Are you looking for a reliable and experienced partner in China for your shell processing sheet metal fabrication needs in the aerospace industry?

More

-

-

China Custom Stainless Steel Sheet Metal Fabrication: Cutting, Bending & Welding

China has firmly established itself as a global powerhouse for advanced manufacturing, and its capabilities in custom stainless sheet metal fabrication in China are truly world-class.

More

-

-

China Manufacturer Aluminum Sheet Metal Fabrication Shell Box

we specialize in delivering high-quality, precision-engineered aluminum sheet metal fabrication solutions tailored to meet the diverse needs of industries worldwide.

More

-

-

Precision Sheet Metal Fabrication and Stamping Services for Custom Metal Components

As a leading China sheet metal fabrication stamping Supplier and China sheet metal fabrication stamping Manufacturer, we specialize in delivering high-quality precision sheet metal fabrication and stamping services tailored to meet the unique needs of our clients.

More

-

-

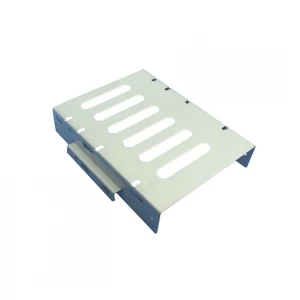

Precision Sheet Metal Fabrication Frames for Industrial Applications – Customizable Sizes and Finishes

Our sheet metal fabrication frames are engineered to withstand the rigors of industrial environments, offering exceptional strength and stability. Whether you require standard sizes or fully customizable dimensions, we provide flexible solutions to fit your specific requirements.

More

-

-

Custom Sheet Metal Fabrication Parts Welding Stamping Cutting Service

Are you looking for a reliable and experienced sheet metal fabrication parts manufacturer in China? Look no further! Our China factory specializes in providing top-quality custom sheet metal fabrication parts that are perfect for a wide range of industries and applications.

More

-

-

High Quality Custom Aluminum Cutting Part and Sheet Metal Fabrication Services

Are you looking for top-notch sheet metal fabrication services in China? Look no further! Our custom sheet metal fabrication services are second to none, providing high quality aluminum cutting parts that are tailor-made to meet your specific needs.

More

-

-

China Supplier Custom OEM Laser Cutting Sheet Metal Fabrication

China Supplier Custom OEM Laser Cutting Sheet Metal Fabrication is a top-notch service offered by a leading manufacturer in the industry.

More