- Contact Us

-

Contact: Devin Liu

E-mail: sales@sheetmetal-fabrication.com

Tel: +86 13382165719

Wechat: LGQ4169719 Contact Now

Contact Now

- New Products

- Latest News

-

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the custom design and fabrication of stainless steel, iron, aluminum, galvanized sheet and other materials. The fabricatio...what is advantage of anodic oxidation and anodized ?

Anodizing (spelled anodizing, in Singapore, the UK, India, and Australia) is an electrolytic passivation process used to increase the thickness of the...China Internation Furniture Fair 2017

From September 11 to 14, 2017, the 40th CIFF Shanghai will present a fantastic feast for the furniture and home furnishings industry. CIFF features th...How coronavirus impact global economy?

The coronavirus outbreak, which originated in China, has infected more than 200,000 people. Its spread has left businesses around the world counting c...

- Subscribe

-

Get email updates on new products

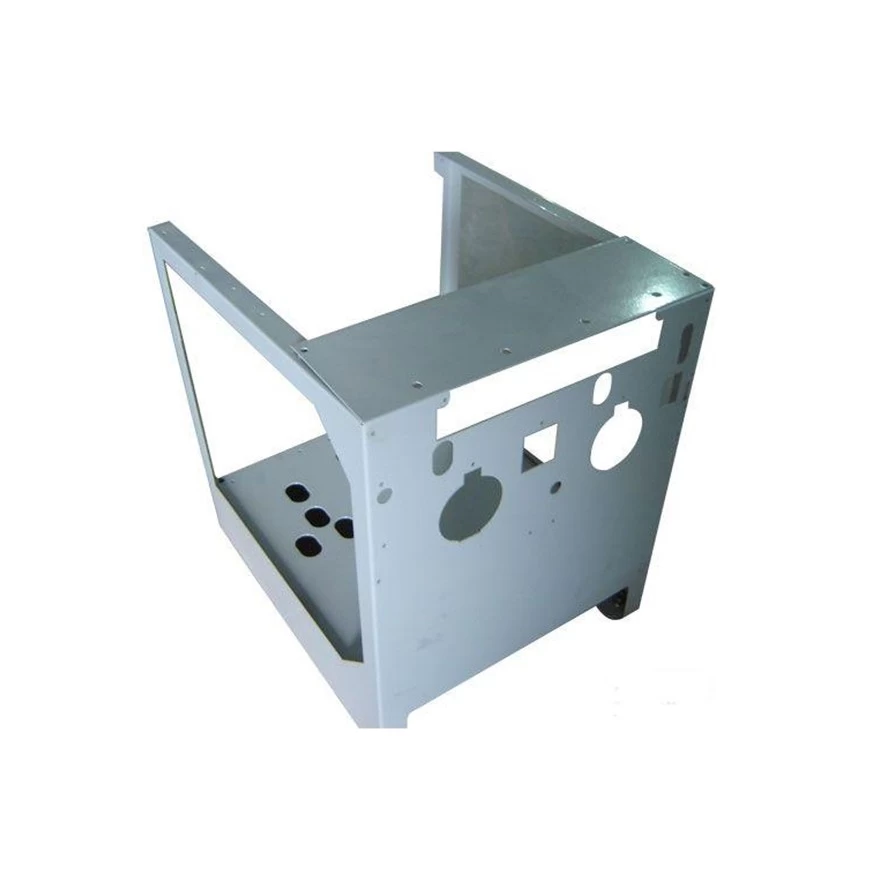

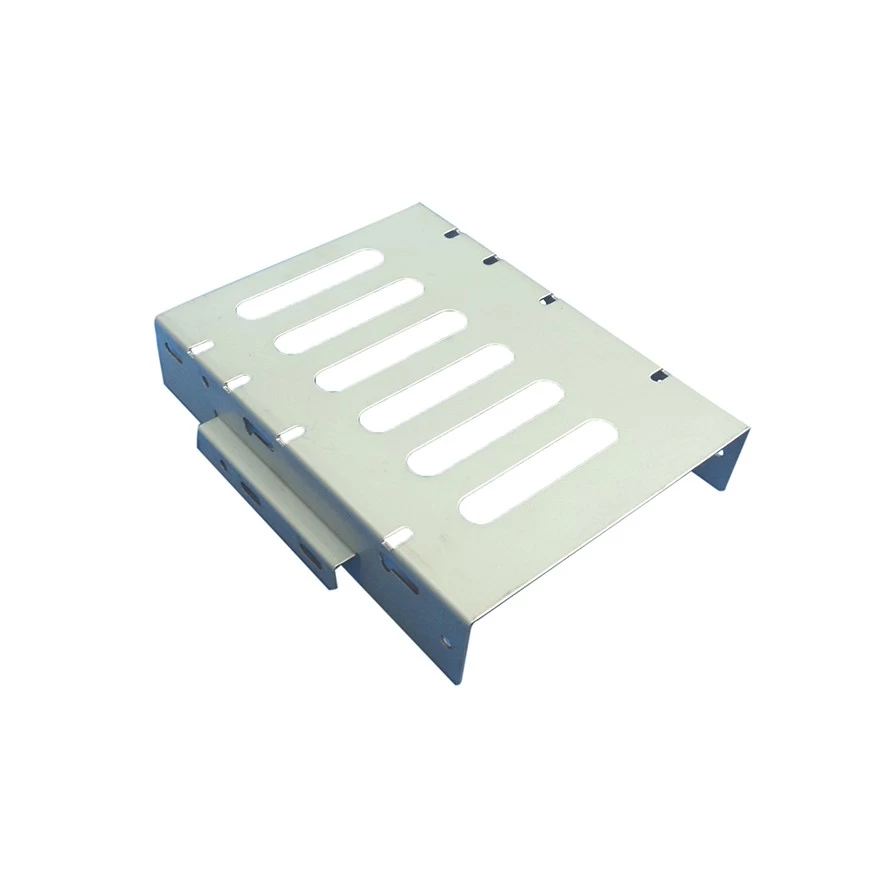

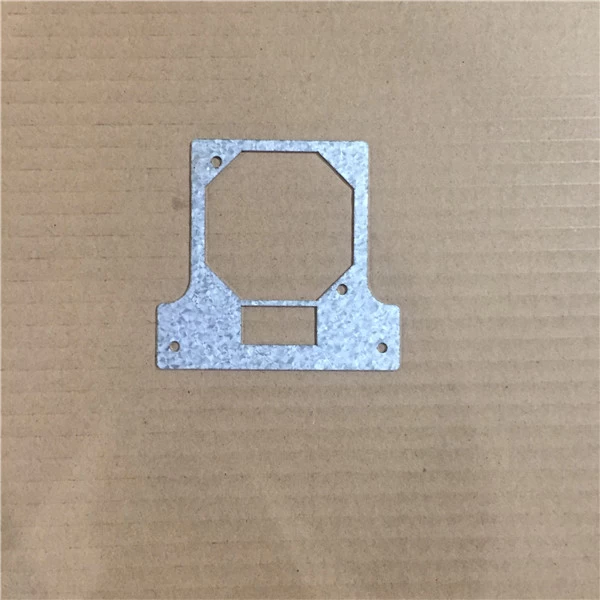

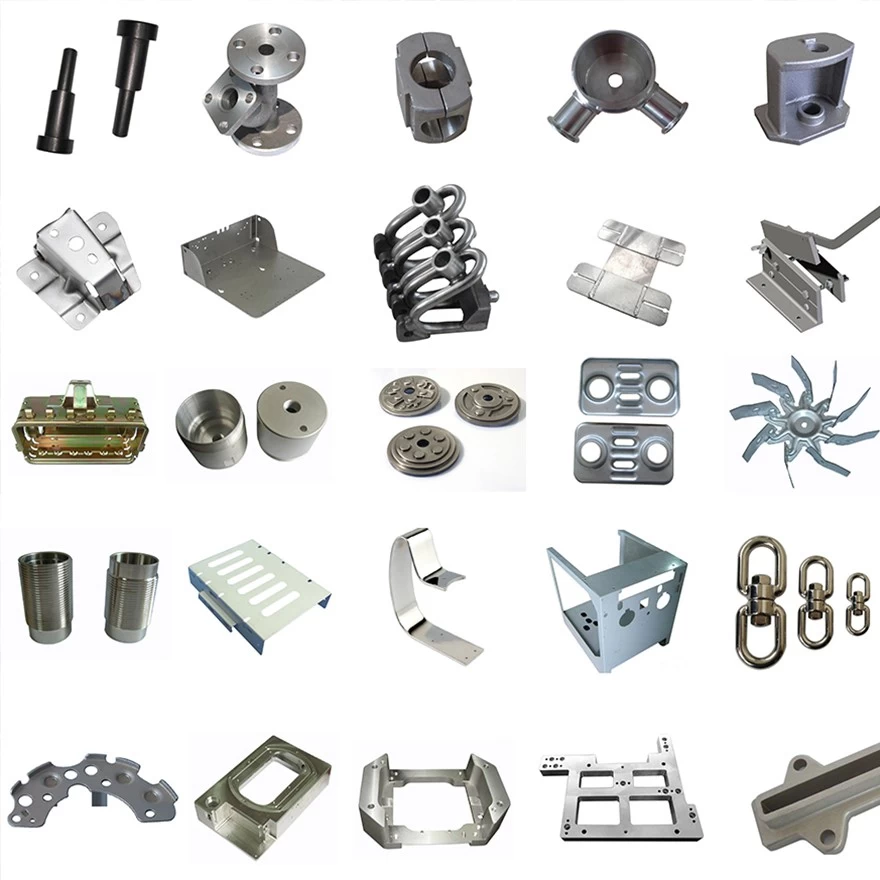

Precision Sheet Metal Fabrication and Stamping Services for Custom Metal Components

- Place of Origin: Jiangsu, China (Mainland)

- Brand Name: HOUDRY

- Model Number: Custom Made

- Certificate: ISO9001:2015/SGS

- Material: Stainless Steel/Iron/Aluminum

- Fabrication Process: Stamping, Bending, Laser Cutting, Welding, Forging, Casting, Maching and so on.

- Tolerance: ±0.1mm

- Surface Treatment: Mirror Polishing, Powder Coat, Zinc Plate, Paint, Brushing as per drawing.

- Service: Custom OEM/ODM sheetmetal fabrication service

- Supplier Type: Manufacturer/Fabcicator/Factory/Designer

- Package: Standard package/individual package for export or as requested.

- Delivery time: 7 - 20 working days or negotiable

| Description |

As a leading China sheet metal fabrication stamping Supplier and China sheet metal fabrication stamping Manufacturer, we specialize in delivering high-quality precision sheet metal fabrication and stamping services tailored to meet the unique needs of our clients. Our China Factory sheet metal fabrication stamping is equipped with state-of-the-art technology and advanced machinery, ensuring the production of custom metal components with exceptional accuracy and durability.

We offer a comprehensive range of services, including laser cutting, bending, welding, and assembly, all designed to provide cost-effective solutions for industries such as automotive, aerospace, electronics, and more. Our team of skilled engineers and technicians work closely with clients to transform their designs into high-performance metal parts, adhering to the strictest quality standards.

Whether you require prototyping or large-scale production, our China sheet metal fabrication stamping capabilities ensure timely delivery and competitive pricing. Partner with us for reliable, precision-engineered metal components that meet your exact specifications.

| Specifications |

| Place of Origin | Jiangsu, China (Mainland) |

| Brand Name | HOUDRY |

| Model Number | Custom Made |

| Certificate | ISO9001:2015/SGS |

| Material | Stainless Steel/Iron/Aluminum |

| Fabrication Process | Stamping, Bending, Laser Cutting, Welding, Forging, Casting, Maching |

| Tolerance | ±0.1mm |

| Surface Treatment | Mirror Polishing, Powder Coat, Zinc Plate, Paint, Brushing as per drawing |

| Service | Custom OEM/ODM sheetmetal fabrication service |

| Supplier Type | Manufacturer/Fabcicator/Factory/Designer |

| Package | Standard package/individual package for export or as requested |

| Delivery time | 7 - 20 working days or negotiable |

| More Products |

| Company Introduction |

Suzhou Houdry Mechanical and Electrical Technology Co., Ltd. is a manufacturing factory which engaged in sheet metal fabrication services since 2008. Now our factory covers 12,000 square meters, with 250 employees including 8 senior engineers and 10 quality engineers. Houdry has good cooperative with SIEMENS, AMADA, AMETEK, OERLIKON, etc. Annual value of $16 million. Houdry can provide various of sheet metal fabrication service, such as sheetmetal stamping parts, laser cutting, cnc machining, welding, bending, forging, casting, etc.and surface treatments such as painting, anodize, power coating, zinc-plating etc.

Our sheet metal fabrication products are widely used in various areas such as cold chain products, net working products, bus air condition unit, invertor metal forming parts and track safety door part.

Our main customers are from overseas markets such as Germany, the United States, the United Kingdom, France, Singapore, and Sweden.

| Our Factory |

Our company can provide various of sheet metal fabrication service, such as sheetmetal stamping parts, laser cutting, cnc machining, welding, bending, forging, casting, etc.and mirror polishing, powder coat, zinc plate, paint, Brushing as per drawing.

| Equipment |

We have laser cutting machine, robot wenlding machine, bending machine, stamping machine, cnc machining centers, milling machine, grinding machine, injecton mold machine and so on equipments. Can produce most metal products.

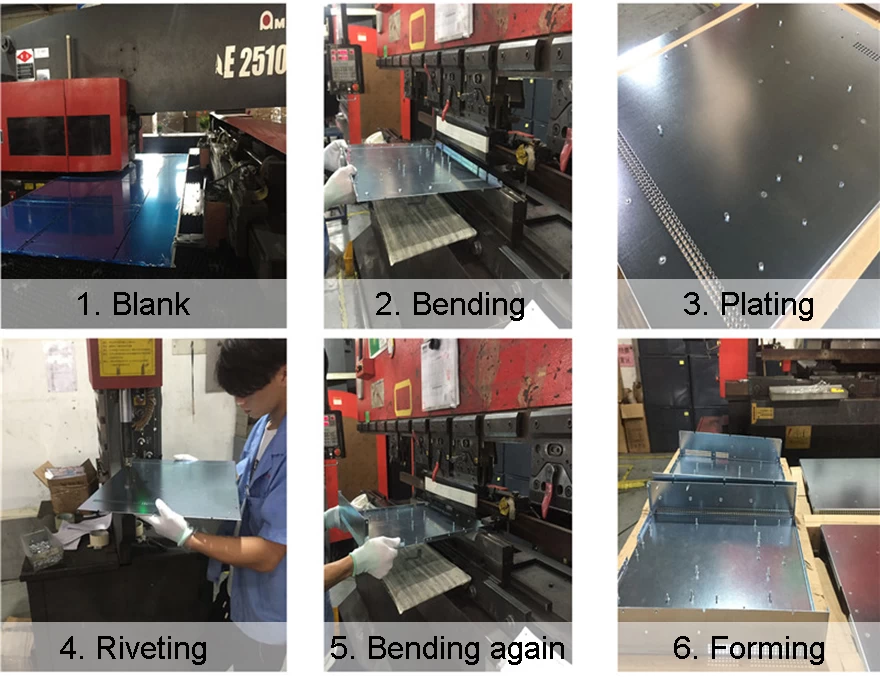

| Production Process |

| Our Package |

Standard package/individual package for export or as requested. Sheet metal parts are usually packed in carton box, then packed in plywood pallets or plywood boxes.

| FAQ |

Question 1: What is Sheet Metal Fabrication Stainless Steel?

Answer: Sheet Metal Fabrication Stainless Steel is the process of cutting, bending, and assembling stainless steel sheets to create various products such as enclosures, brackets, panels, and more. This method allows for the customization of stainless steel components for different applications.>

Question 2: What are the advantages of using Stainless Steel in Sheet Metal Fabrication?

Answer: Stainless steel offers excellent corrosion resistance, durability, and strength, making it ideal for a wide range of applications. It is also aesthetically pleasing, easy to clean, and can withstand high temperatures, making it suitable for various industries, including automotive, aerospace, and food processing.

Question 3: How is Stainless Steel sheet metal fabricated?

Answer: Stainless Steel sheet metal fabrication involves several steps, including cutting the stainless steel sheet to the desired size, bending it into the required shape using specialized equipment, and assembling the pieces through welding or fastening methods. The final product is then finished with surface treatments such as polishing or coating.

Question 4: What are the applications of Sheet Metal Fabrication Stainless Steel?

Answer: Sheet Metal Fabrication Stainless Steel is used in a wide range of industries for various applications, including manufacturing of kitchen equipment, medical devices, architectural components, automotive parts, and more. Its versatility and durability make it a popular choice for many projects.

Question 5: How can I ensure the quality of Sheet Metal Fabrication Stainless Steel products?

Answer: To ensure the quality of Sheet Metal Fabrication Stainless Steel products, it is essential to work with a reputable and experienced fabricator who uses high-quality materials, advanced equipment, and follows strict quality control measures. Inspecting the finished products for accuracy, strength, and finish is also crucial.

Question 6: Can Sheet Metal Fabrication Stainless Steel be customized according to specific requirements?

Answer: Yes, Sheet Metal Fabrication Stainless Steel can be customized to meet specific design, size, and functional requirements. Fabricators can work closely with clients to understand their needs and create custom solutions that meet their exact specifications.

Tel:8613382165719

Wechat:LGQ4169719

Facebook:ahlgq2000@163.com

Contact Person:Devin Liu

PDF Show:PDF