- Contact Us

-

Contact: Devin Liu

E-mail: sales@sheetmetal-fabrication.com

Tel: +86 13382165719

Wechat: LGQ4169719 Contact Now

Contact Now

- New Products

- Latest News

-

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the custom design and fabrication of stainless steel, iron, aluminum, galvanized sheet and other materials. The fabricatio...what is advantage of anodic oxidation and anodized ?

Anodizing (spelled anodizing, in Singapore, the UK, India, and Australia) is an electrolytic passivation process used to increase the thickness of the...China Internation Furniture Fair 2017

From September 11 to 14, 2017, the 40th CIFF Shanghai will present a fantastic feast for the furniture and home furnishings industry. CIFF features th...How coronavirus impact global economy?

The coronavirus outbreak, which originated in China, has infected more than 200,000 people. Its spread has left businesses around the world counting c...

- Subscribe

-

Get email updates on new products

Category

-

-

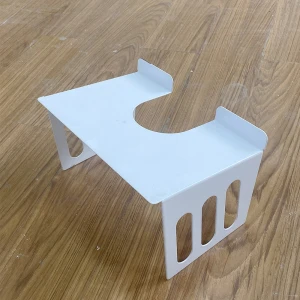

China Manufacturer Sheet Metal Fabrication Sheet Metal Stamping Design

As a China Sheet Metal Bending Bracket Manufacturer with deep industry expertise, we not only specialise in the bespoke production of high-precision sheet metal bending brackets but also leverage our core capabilities as a China Sheet Metal Stamping Factory to provide comprehensive sheet metal stamping solutions for global clients.

More

-

-

China Heavy Duty Sheet Metal Parts cabinet Steel Shop Cabinets

As a leading China Industrial Metal Storage Cabinet Manufacturer, we specialize in producing heavy-duty sheet metal parts and robust storage solutions built for demanding industrial environments.

More

-

-

China Manufacturer Industrial Metal Storage Cabinet Sheet Metal Parts

As a leading company deeply rooted in the metal storage field, we empower industrial storage upgrades with professional manufacturing, making us a trustworthy China Steel Drawer Cabinet Manufacturer.

More

-

-

China Sheet Metal Fabrication Factory Steel Drawer Cabinet Manufacturer

As a dedicated China Industrial Storage Cabinets with Drawers Manufacturer, we specialize in transforming high-quality steel into cabinets that redefine durability—each piece crafted through advanced sheet metal fabrication techniques, ensuring consistent performance even in harsh factory, warehouse, or workshop environments.

More

-

-

China Manufacturer Sheet Metal Fabrication Industrial Storage Cabinets with Drawers

Crafted with meticulous attention to detail, these cabinets are built to withstand the rigors of industrial environments, thanks to their core component—high-grade steel sourced and processed by our expert team as a leading China Heavy Duty Steel Cabinet Manufacturer.

More

-

-

China Manufacturer Sheet Metal Fabrication Custom Heavy Duty Steel Cabinet

As a professional China heavy duty steel storage cabinets Manufacturer, we specialize in sheet metal fabrication to deliver high-quality custom heavy duty steel cabinets tailored to diverse industrial and commercial needs.

More

-

-

China Sheet Metal Fabrication Heavy Duty Steel Storage Cabinets Manufacturer

As a leading China industrial storage cabinet factory, we specialize in high-performance solutions for the most demanding environments. Our expertise in precision sheet metal fabrication allows us to produce unparalleled China steel storage cabinets known for their exceptional strength and durability.

More

-

-

China Sheet Metal Bending Manufacturer Sheet Metal Bending Bracket

If you're looking for a reliable China sheet metal bending supplier, we're your ideal choice. We specialize in precision sheet metal manufacturing, equipped with advanced bending equipment and proven processes, and are committed to providing you with high-quality, efficient, and competitive products and services.

More

-

-

China Custom Galvanized Sheet Metal Fabrication Service

For engineers, product developers, and businesses worldwide, accessing China custom galvanized sheet metal fabrication service has become a strategic imperative for bringing robust, high-quality, and cost-effective products to market. This sector excels by combining advanced technology, skilled labor, and immense production capacity to meet diverse and demanding specifications.

More

-

-

China Special Metal Stamping Factory Custom Metal Stamps for Metal

For businesses and engineers seeking custom metal stamps for specialized applications, partnering with a dedicated China stamping aluminum sheet metal factory offers unparalleled advantages.

More

-

-

China Sheet Metal Manufacturing Companies Low Volume Sheet Metal Stamping

At our state-of-the-art manufacturing facility in China, we understand that innovation doesn't always start with a massive production order. It begins with a prototype, a design validation, or a specialized low-volume run. That’s where our expertise shines.

More

-

-

China Prototype Aluminum Sheet Metal Stamping Factory

Welcome to our state-of-the-art facility, a leading China custom sheet metal stamping manufacturer dedicated to turning your concepts into high-quality, tangible reality. We specialize in transforming raw aluminum and various metals into precise, durable components that meet the most stringent specifications.

More