- Contact Us

-

Contact: Devin Liu

E-mail: sales@sheetmetal-fabrication.com

Tel: +86 13382165719

Wechat: LGQ4169719 Contact Now

Contact Now

- New Products

- Latest News

-

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the custom design and fabrication of stainless steel, iron, aluminum, galvanized sheet and other materials. The fabricatio...what is advantage of anodic oxidation and anodized ?

Anodizing (spelled anodizing, in Singapore, the UK, India, and Australia) is an electrolytic passivation process used to increase the thickness of the...China Internation Furniture Fair 2017

From September 11 to 14, 2017, the 40th CIFF Shanghai will present a fantastic feast for the furniture and home furnishings industry. CIFF features th...How coronavirus impact global economy?

The coronavirus outbreak, which originated in China, has infected more than 200,000 people. Its spread has left businesses around the world counting c...

- Subscribe

-

Get email updates on new products

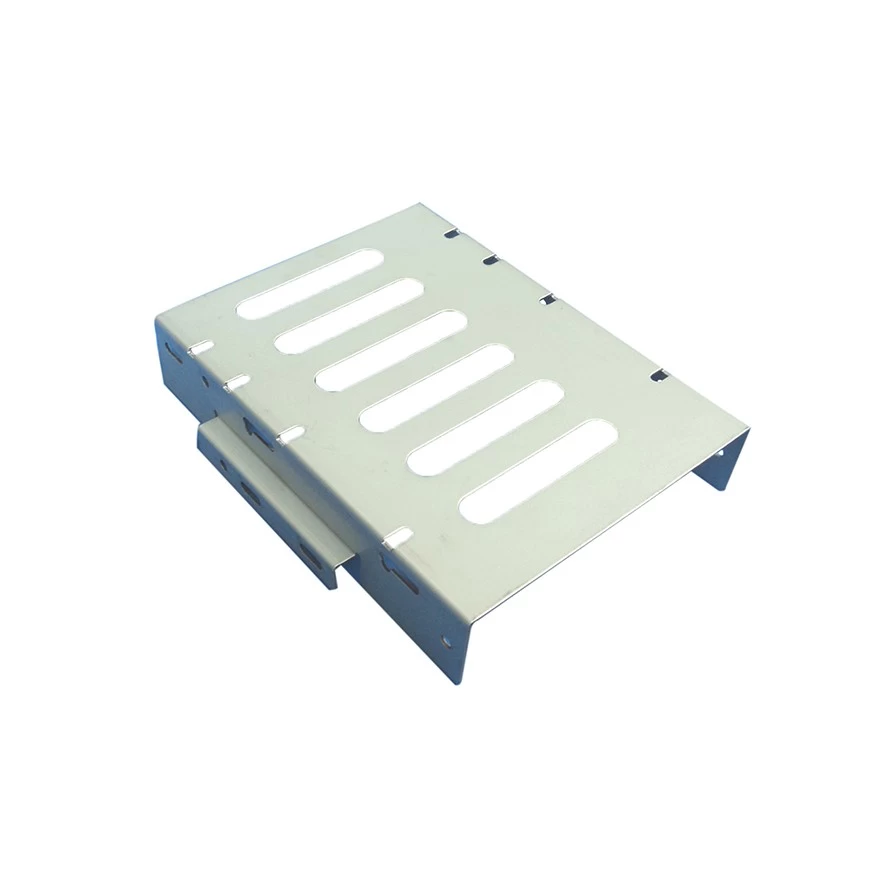

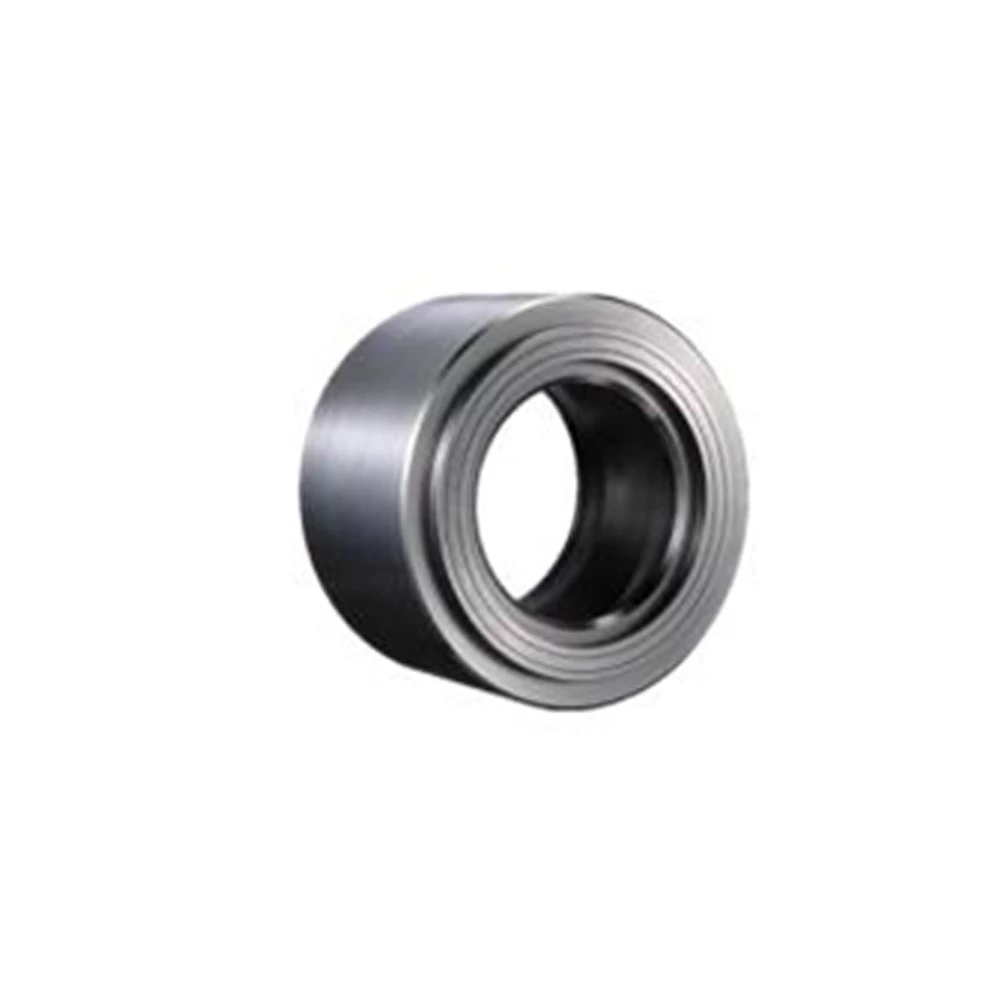

custom sheet metal with bending , tapping, punching, eletrical plating treatment

- all kinds of metal materials available,include steel,aluminum,copper,brass,stainless steel etc.

- Completely equipments include cutting,bending,stamping,CNC,welding etc.

- Various surface treatment support such as power coating,anodizing,polishing,plating etc.

- Strict quality control system,IQC,IPQC,OQC etc.

Cooperation model: OEM or ODM

Design: As per customer specific requirements

or customer give us the specified sample;

or the customer conceptual or preliminary design;

or the customer sketched idea.

Accept drawing format: .jpg / .dwg / .igs / .stp etc..

Material: Sheet stock is of many materials, including

carbon steel, alloy steel, stainless steel, aluminum, brass even plastics.

Material condition: On flat sheet, plate coil supplying condition

Hot rolled or cold rolled or cold drawn for options.

Material thickness: From 0.2mm~6mm

Application material standard:

If there is no any specially requirement, we often sugguest our customer to try the equivalent China National (GB) standard material that our engineering team proposes which to be properly converted from ANSI, ASTM, SAE, EN, DIN, BS, JIS, and etc., to contribute the material cost control.

If it is necessary to use exact designated material no., it is also possible choice.

Available processing (Technique):

- Shearing - Crimping - Laser cutting - Bending - Stamping - Pressing

- Deep drawing - Rolling - Forming - Fabricating - Drilling

- Tapping - Riveting - Spot welding - TIG - Assembling

Precision: Average level: ±0.05mm, depending the part size and thickness and material

Design: As per customer specific requirements

or customer give us the specified sample;

or the customer conceptual or preliminary design;

or the customer sketched idea.

Accept drawing format: .jpg / .dwg / .igs / .stp etc..

Material: Sheet stock is of many materials, including

carbon steel, alloy steel, stainless steel, aluminum, brass even plastics.

Material condition: On flat sheet, plate coil supplying condition

Hot rolled or cold rolled or cold drawn for options.

Material thickness: From 0.2mm~6mm

Application material standard:

If there is no any specially requirement, we often sugguest our customer to try the equivalent China National (GB) standard material that our engineering team proposes which to be properly converted from ANSI, ASTM, SAE, EN, DIN, BS, JIS, and etc., to contribute the material cost control.

If it is necessary to use exact designated material no., it is also possible choice.

Available processing (Technique):

- Shearing - Crimping - Laser cutting - Bending - Stamping - Pressing

- Deep drawing - Rolling - Forming - Fabricating - Drilling

- Tapping - Riveting - Spot welding - TIG - Assembling

Precision: Average level: ±0.05mm, depending the part size and thickness and material

Tag:

sheet metal fabrication

,custom sheet metal part

,Laser Cutting

,china laser cutting service

,china sheet metal manufacturer

,CNC punching service

,metal stamping

Suzhou Houdry Mechanical and Electrical Technology Co.,Ltd

Tel:8613382165719

Wechat:LGQ4169719

Facebook:ahlgq2000@163.com

Contact Person:Devin Liu

PDF Show:PDF