What are the requirements for sheet metal fabrication in aviation?

China sheetmetal fabrication technology plays a key role in aerospace engineering projects and is also one of the key technologies to maintain the structural characteristics of airports. The key to contemporary airport shells is sheet metal riveted construction. Statistics show that sheet metal parts account for about 50% of the total number of airport parts, sheet metal technology weapons and equipment account for about 65% of the whole machine manufacturing and processing technology weapons and equipment, and its manufacturing labor accounts for about 20% of the whole machine labor force. Due to the airport's structural characteristics and unique lean production methods, the airport's sheet metal fabrication technology is different from the general machinery manufacturing basis.

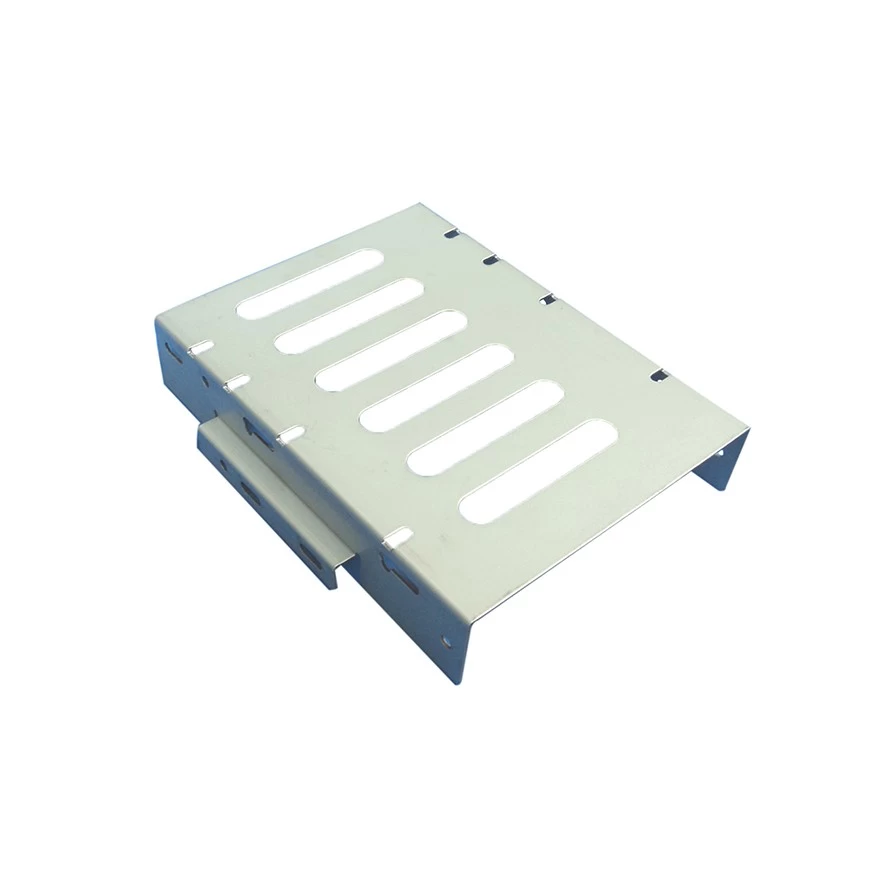

Sheet metal parts fabrication constitutes the airport's human body and aerodynamic exterior design. China sheet metal parts constitute the structure and aerodynamic appearance design of the airport human body. The parts have different sizes, complex appearances, different material selections, different production volumes, and a complete range of varieties. Sheet metal processing parts have complex appearance, strict quality management, certain service life regulations, and regulations on physical and process performance of formed parts. Compared with sheet metal parts in other industries, the technical standards are higher and the difficulty factor is greater. The production and manufacture of sheet metal parts should be based on professional equipment, combined with the actual operation of manual craftsmanship and work experience.

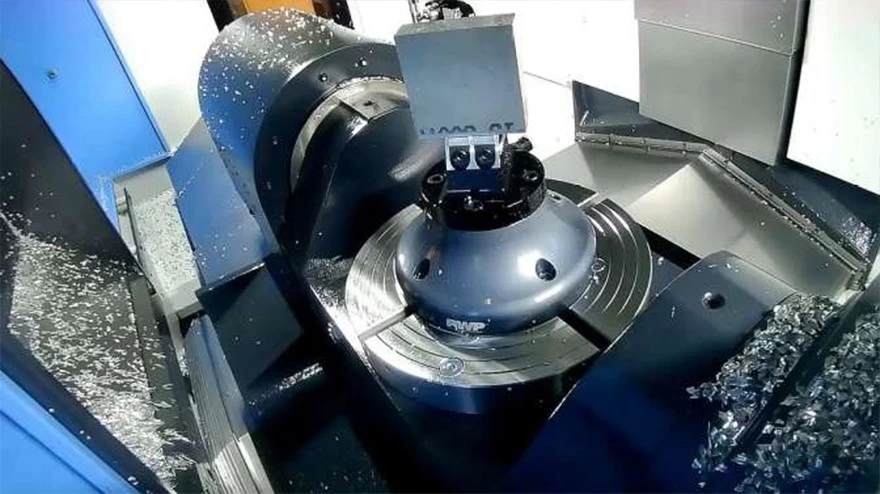

Sheet metal parts equipment is a symbol of the development trend of airport sheet metal processing technology. It is the carrier of the results of pre-research on production processes and plays a fundamental role in the quality of parts molding. This mechanical equipment has a long research and development period, high technological content, large project investment, small social development needs, low utilization rate of mechanical equipment, and slow upgrade of mechanical equipment. It is stipulated that technicians must have excellent manual production skills.

The requirements for sheet metal fabrication in aviation are as follows:

1. Compliance with aviation regulations: All sheet metal fabrication in aviation must comply with the regulations set by the aviation authorities, such as the Federal Aviation Administration (FAA) in the United States. These regulations ensure that the fabricated parts meet the necessary safety and quality standards.

2. Material selection: The sheet metal used in aviation must be selected carefully to meet specific requirements, such as strength, weight, and resistance to corrosion. Commonly used materials include aluminum alloys, stainless steel, and titanium.

3. Precision and accuracy: Aviation sheet metal fabrication requires high precision and accuracy to ensure proper fit and function of the fabricated parts. This includes precise cutting, bending, and shaping of the sheet metal components.

4. Welding and joining techniques: Sheet metal parts in aviation are often joined using welding techniques. Fabricators must have expertise in various welding methods, such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and spot welding, to ensure strong and reliable connections.

5. Quality control and inspection: Stringent quality control measures are essential in aviation sheet metal fabrication. Fabricators must perform thorough inspections and tests to ensure that the fabricated parts meet the required standards. This may include visual inspections, dimensional checks, non-destructive testing (NDT), and material testing.

6. Documentation and traceability: In aviation, documentation and traceability are crucial. Fabricators must maintain detailed records of the fabrication process, including material certifications, inspection reports, and any repairs or modifications made to the fabricated parts. This documentation ensures accountability and facilitates traceability throughout the life cycle of the aircraft.

7. Continual training and certification: Fabricators involved in aviation sheet metal fabrication must undergo regular training and certification to stay updated with the latest techniques, regulations, and safety practices. This ensures that they have the necessary skills and knowledge to meet the stringent requirements of the aviation industry.