Large Custom Metal Fabrication: When Steel is Given Soul and Purpose

At the very backbone of the industrial world, a field transforms cold metal into the powerful bones that power modern civilization: China large custom metal fabrication manufacturer. Far more than simple cutting and welding, it's a comprehensive art form that blends cutting-edge engineering, state-of-the-art design, and rigorous craftsmanship. Each unique component created is the perfect realization of a client's specific vision and complex functional requirements.

What is Large Custom Metal Fabrication?

Unlike standardized, mass-produced production lines, large custom metal fabrication specializes in creating unique, large-scale metal structures and components tailored to specific projects. The "large" aspect of this approach is reflected in the scale and weight of the products, which often require extensive workshops, heavy lifting equipment, and precision machinery. "Customization" is at its core, meaning that every step, from concept design to final product, is centered around the client's unique needs.

Its Applications are Extremely Broad, Encompassing the Following:

Architecture and Structures: The distinctive facades of skyscrapers, the dome trusses of large stadiums, airport canopies, and complex staircase and railing systems.

Energy and Power: Wind turbine towers and bases, the massive penstocks of hydroelectric power plants, the protective structures of nuclear power facilities, and transmission towers.

Heavy Machinery and Transportation: The massive chassis of mining machinery, ship superstructures, the booms of port cranes, and the frames of large transport equipment.

Resources and Infrastructure: The massive reaction vessels of petrochemical plants, the sedimentation tanks of water treatment plants, and the support structures of large storage systems.

The Core Processes Behind Manufacturing Excellence

A high-quality, China large custom metal fabrication product is the product of a series of precise and coherent processes:

Engineering and Design: This is the "brain" of the project. Engineers use advanced CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) software to perform 3D modeling, stress analysis, and simulation testing to ensure design feasibility, safety, and optimization.

Material Selection and Pretreatment: Appropriate metal materials, such as carbon steel, stainless steel, aluminum alloy, or specialty alloys, are selected based on the product's application requirements (e.g., corrosion resistance, high-temperature resistance, and load-bearing capacity). Materials undergo sandblasting and pretreatment prior to processing to ensure optimal surface conditions.

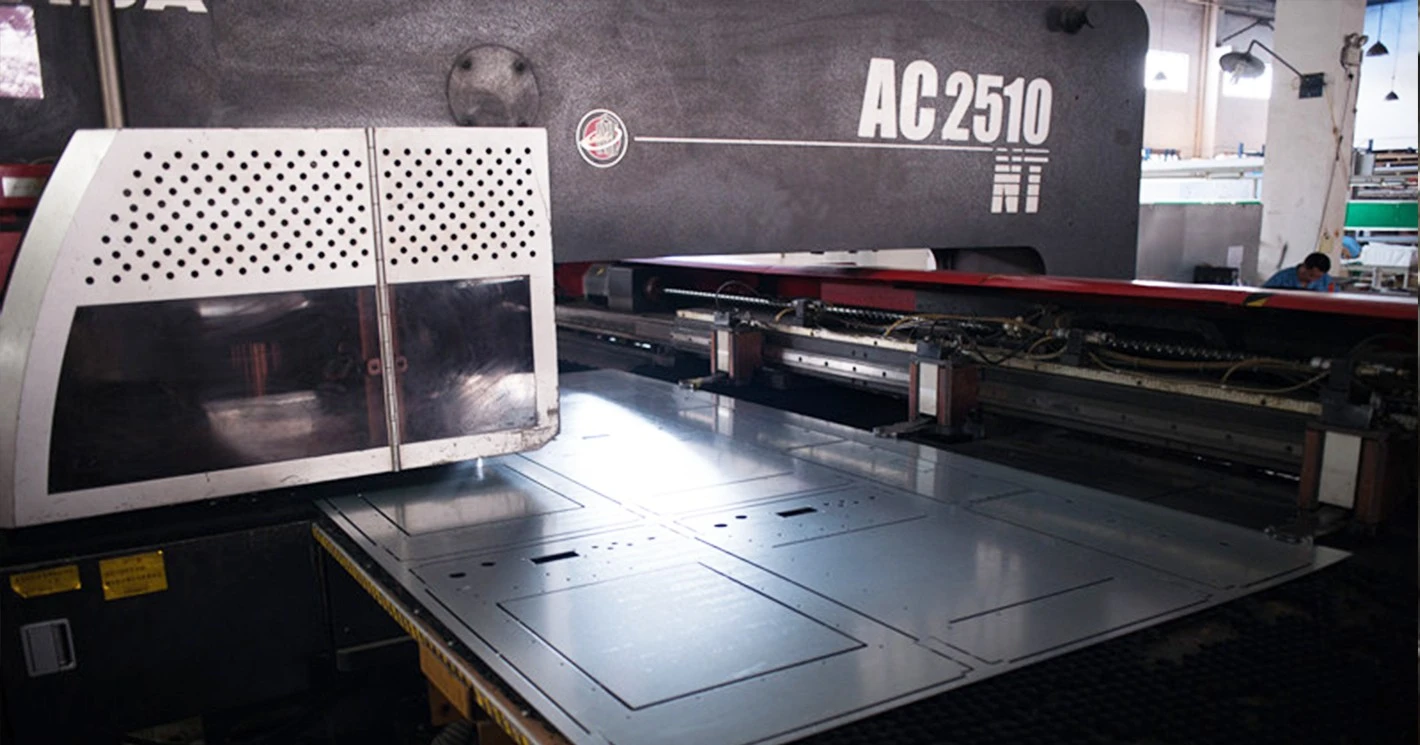

Precision Cutting and Forming: Sheet metal is precisely cut into the desired shape using ultra-high-power laser cutting, plasma cutting, or water jet cutting. Large-scale press brakes, plate rolling machines, or forging equipment are then used to bend, roll, or stamp the product into the designed three-dimensional form.

Welding and Assembly: This is the critical step that brings the component to life. Certified welders utilize processes such as MIG/TIG and submerged arc welding to securely join the individual components into a single, integrated unit. Assembling large workpieces requires exceptional craftsmanship and extensive experience to ensure precise alignment.

Fine Machining and Surface Treatment: After completion, the product undergoes machining (such as milling and drilling) to achieve precise dimensional tolerances. Surface treatments (such as painting, hot-dip galvanizing, epoxy spraying, or metal plating) provide long-term protection and an aesthetically pleasing appearance.

Quality Assurance and Testing: Quality is prioritized throughout. From incoming raw material inspection to in-process dimensional verification and final non-destructive testing (NDT) such as X-rays, ultrasonic testing, and magnetic particle inspection, we ensure that every weld and structure is flawless and meets the most stringent industry standards.

Conclusion

Large custom metal fabrication is the silent cornerstone of modern industry, hidden behind magnificent buildings, powerful machines, and critical infrastructure. It represents a capability—the ability to transform wildly imaginative blueprints into solid, reliable industrial realities that endure for decades. In this field, metal is no longer a cold material; it is imbued with soul and purpose, continuously shaping the shape and future of our world.