How Precision Sheet Metal Fabrication Powers Modern Mechanical Parts

The unsung hero of our industrial world often arrives flat, coiled, and unassuming: sheet metal. Yet, through the transformative power of sheet metal fabrication services, this raw material becomes the robust skeleton, the protective casing, and the intricate functional components that drive countless machines, devices, and structures. For engineers, designers, and procurement specialists sourcing mechanical parts, understanding the capabilities and value of professional sheet metal fabrication is paramount.

This guide delves into the world of sheet metal fabrication services specifically for mechanical components, exploring the processes, materials, advantages, and key considerations when choosing a partner.

What is Sheet Metal Fabrication for Mechanical Parts?

At its core, China manufacturer precision sheet metal is a collection of subtractive and forming manufacturing processes used to transform flat sheets of metal (typically ranging from ultra-thin foils up to plates around 1/4 inch or 6mm thick) into specific three-dimensional parts or assemblies. Unlike casting or machining from solid blocks, fabrication builds parts by cutting, bending, and joining metal sheets.

Why Choose Sheet Metal for Mechanical Components?

1. Cost-Effectiveness (Especially at Volume): Once tooling (like press brake dies, punch patterns) is established, producing parts via fabrication is often significantly cheaper per unit than CNC machining solid blocks, particularly for thin-walled or enclosure-type components.

2. High Strength-to-Weight Ratio: Sheet metal parts, especially when formed into stiffening shapes (ribs, bends, flanges), offer excellent strength and rigidity without excessive weight – crucial in applications like aerospace frames, machinery guards, and automotive brackets.

3. Speed and Scalability: Fabrication processes like laser cutting and CNC punching are extremely fast. Combined with efficient bending and welding, this allows for rapid prototyping and seamless scaling to high-volume production runs.

4. Design Flexibility & Complexity: Modern CAD/CAM software and advanced machinery enable the creation of highly complex geometries with precision cutouts, intricate bends, and formed features that would be difficult or impossible with other methods.

5. Material Versatility: A vast array of metals can be fabricated, allowing engineers to select the perfect material for strength, corrosion resistance, conductivity, weight, or cost requirements (more on materials below).

6. Excellent Surface Finish Options: Fabricated parts can be easily finished through powder coating, painting, plating, anodizing (for aluminum), or polishing, enhancing aesthetics, durability, and corrosion resistance.

7. Durability and Longevity: Properly fabricated and finished sheet metal parts are renowned for their toughness and ability to withstand harsh environments, vibration, and impact.

Applications: Where Fabricated Mechanical Parts Shine

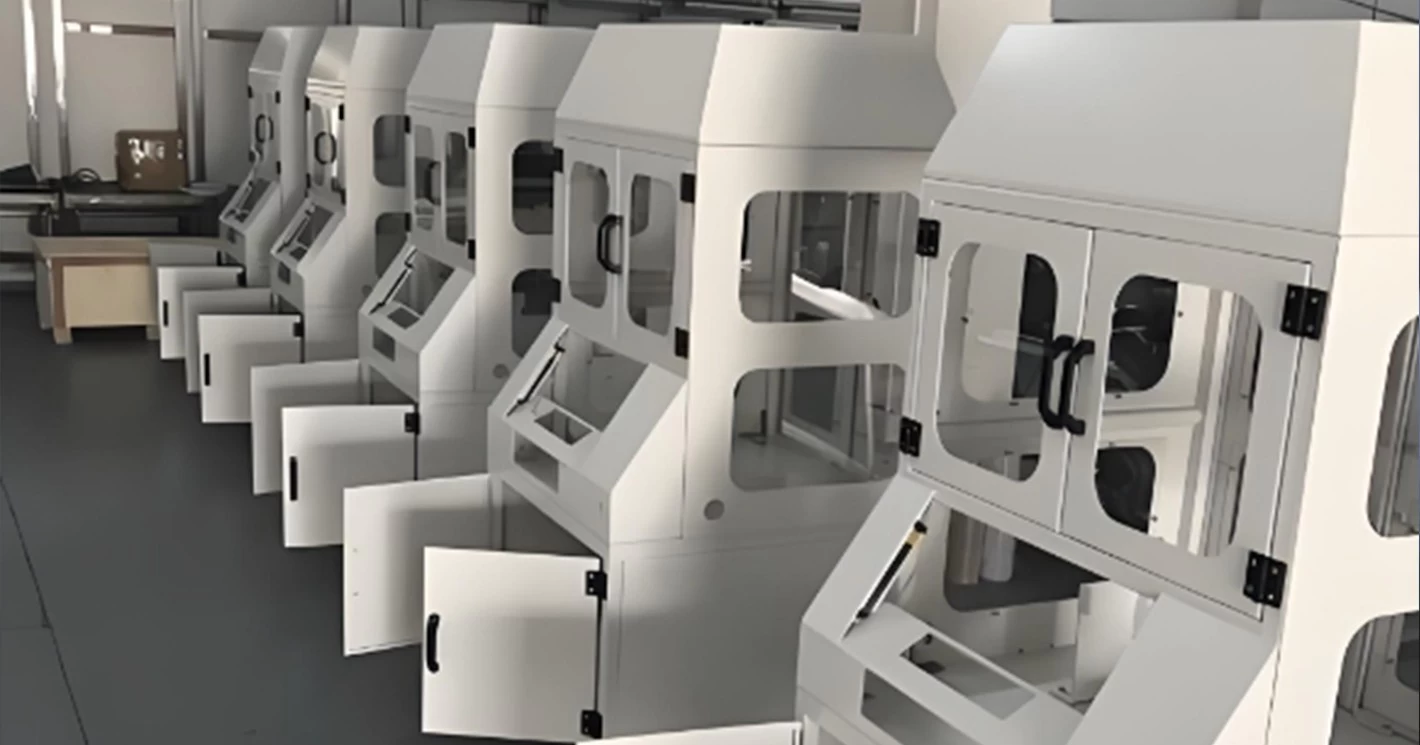

Enclosures & Cabinets: Electrical panels, server racks, machine guards, control boxes, junction boxes.

Brackets & Mounts: Engine mounts, sensor holders, equipment supports, structural frames.

Chassis & Frames: Equipment bases, robotic arms, conveyor system frames, vehicle subframes.

Heat Sinks & Cooling Systems: Fins, shrouds, ducts for thermal management.

Fluid & Pneumatic Systems: Tanks, reservoirs, ducting, manifolds.

Conveyor Components: Guides, trays, supports.

Agricultural & Construction Machinery: Housings, covers, structural elements.

Medical Equipment: Carts, instrument housings, trays (often stainless or aluminum).

Aerospace Components: Non-critical structural parts, brackets, ducting (often aluminum or titanium).

Consumer Products: Appliance housings, furniture frames, lighting fixtures.

Choosing the Right Sheet Metal Fabrication Partner:

Selecting a service provider is critical to the success of your mechanical parts. Consider these factors:

Technical Capabilities & Equipment: Do they have the right machines (laser/punch/waterjet capabilities, modern CNC press brakes, welding expertise) for your part's complexity, tolerances, and material? Ask about their maximum sheet size and thickness capacity.

Engineering & Design Support (DFM): Can they provide Design for Manufacturability feedback before you finalize your design? This is invaluable for optimizing cost, manufacturability, and quality. Look for skilled engineers on staff.

Quality Systems & Certifications: What quality standards do they adhere to (ISO 9001 is common)? What inspection equipment do they use (CMMs, optical comparators, calipers, micrometers)? Do they offer material certifications?

Material Sourcing & Expertise: Can they source the specific grade and finish you require reliably? Do they have expertise working with your chosen material?

Prototyping & Volume Flexibility: Can they efficiently produce low-volume prototypes and scale to production runs? What are their lead times for each?

Finishing Capabilities: Do they offer in-house finishing (powder coating, plating, etc.) or manage trusted partners? This simplifies logistics and quality control.

Experience in Your Industry: Familiarity with your sector's specific standards, challenges, and requirements is a significant advantage.

Communication & Responsiveness: Clear, timely communication throughout the quoting and production process is essential.

Location & Logistics: Consider shipping costs and lead times, though global sourcing is common.

The Future: Automation and Integration

China precision metal fabricators continues to evolve rapidly:

Increased Automation: Robotic welding, material handling, and even bending are becoming more prevalent, boosting speed, consistency, and reducing labor costs.

Software Integration: Seamless CAD/CAM to machine communication (often via DXF files) minimizes errors and streamlines programming. Cloud-based quoting and order tracking are improving.

Laser Technology Advancements: Higher power, faster speeds, and improved precision constantly push the boundaries.

Additive Manufacturing Integration: Hybrid approaches where 3D printing is used for complex features integrated onto fabricated bases are emerging.

Sustainability Focus: Efficient nesting software minimizes scrap. Recycling of metal offcuts is standard practice. More environmentally friendly finishing options are in demand.

Conclusion: The Foundation of Mechanical Innovation

China precision custom sheet metal manufacturer are not just about cutting and bending metal; they are about transforming engineering vision into robust, functional, and cost-effective mechanical reality. From the simplest bracket to the most complex enclosure assembly, precision fabrication underpins countless industries. By understanding the processes, materials, and capabilities involved, and by carefully selecting a fabrication partner that aligns with your technical needs and quality expectations, you unlock a powerful manufacturing solution capable of delivering high-performance mechanical parts that drive innovation forward. Whether you're iterating on a prototype or ramping up for mass production, leveraging the expertise of a skilled sheet metal fabricator is an investment in quality, efficiency, and the success of your mechanical designs.