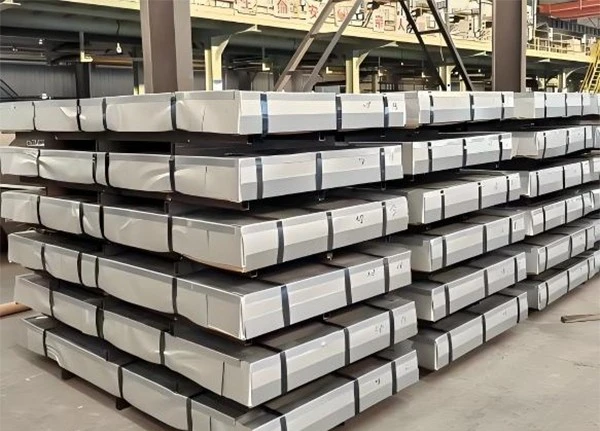

Galvanized Sheet Metal Fabrication: Creating a Strong and Corrosion-Resistant Modern Skeleton

At the heart of countless industrial products in architecture, automobiles, home appliances and even all around us, there is a material that quietly supports the modern world with its unique dual appeal - the strength of steel and the everlasting guardianship of zinc: Galvanized Sheet Metal Fabrication is the process by which cold, hard steel is transformed into a layer of shiny, silvery zinc that is both corrosion-resistant and tough. This article explores the sophisticated world of galvanized steel fabrication and reveals how it is transformed from a flat sheet into a robust and durable component.

Zinc Armor Plus: The Rugged Underpinning of Galvanized Steel

The superior performance of China galvanized sheet metal fabrication begins with its unique protective layer:

Steel Core: Provides the foundation of strength and rigidity needed for the structure.

The zinc shield: Through the chemistry of the sacrificial anode (zinc corrodes in preference to iron), it creates an active layer of protection against environmental aggression.

Process Options: There are two main types of galvanizing: hot dip galvanizing (where the steel sheet is immersed in a bath of molten zinc to form a thicker alloy layer) and electro-galvanizing (electrolytic deposition for a more uniform and smooth surface), to suit different application requirements. The thickness of hot dip galvanizing layer is usually between 70-150 microns, providing longer lasting protection.

Precision work: the art of manufacturing galvanized steel

Turning China custom galvanized sheet metal into practical components requires a series of sophisticated and professional processing technologies:

Cutting: the starting point for precision

Laser cutting: High-energy laser beams to achieve fine cutting of complex contours, with a small heat-affected zone, smooth cutting seams and an accuracy of up to ± 0.1mm, is the first choice for precision parts.

Plasma cutting: high-speed plasma arc suitable for medium-thick plate (usually more than 3mm) efficient cutting, relatively low cost, but the heat affected zone is slightly larger.

Waterjet Cutting: Utilizes an ultra-high pressure water stream (often mixed with abrasive) for cold cutting, completely free of heat effects, suitable for occasions where the integrity of the zinc layer is required to be extremely high or for composite materials.

Punching/Step punching: Efficient mass production using dies or punches, especially for standardized holes and simple shaped parts.

Forming: Giving shape and function

Bending: Pressure forming of the sheet on a bending machine using special dies (V-grooves). The key points are:

Orientation: the plate should be bent as far as possible in the direction of rolling to minimize the risk of cracking.

Minimum internal bending radius: need to be greater than the material allowable (usually 0.5-1 times the thickness of the plate) to avoid zinc flaking or tearing of the substrate.

Mold selection: Use sharp, smooth molds to minimize scratching of the zinc layer.

Roll Forming: Continuous bending by a series of rollers to produce long specific cross-section profiles (e.g. C-beams, corrugated sheets).

Stamping/deep drawing: Use of dies in a press to achieve complex three-dimensional shapes, requiring high material ductility and attention to the lubricating properties of the zinc coating.

Connections: Building the whole

Welding (with special care):

Ventilation is essential: the zinc layer evaporates at high welding temperatures (boiling point approx. 907°C), generating zinc oxide-containing fumes, which must be equipped with a strong local exhaust ventilation system to protect the operator's health.

Selection of welding consumables: silicon bronze wire (e.g. ERCuSi-A) or mild steel wire with special gases (e.g. argon-rich mixtures) is usually used to reduce zinc burn and porosity. MIG welding is relatively common.

Parameter adjustment: Appropriately increase the voltage/current to speed up the welding speed and reduce heat input, which helps to reduce zinc burn and porosity tendency. Clean the zinc layer near the bevel (about 10-20mm wide) before welding is a common and effective method.

Mechanical connection: Bolting, riveting, self-tapping screws are safer options to avoid heat impact and fume problems, and sealing at the connection point should be considered for corrosion protection.

Bonding: Use special metal structure adhesive, suitable for some non-main bearing structure or need to avoid deformation occasions.

Quality and Challenges: In Pursuit of Perfection

Processing galvanized steel presents unique challenges:

Zinc Layer Protection: All operations (handling, processing, storage) need to avoid damaging the zinc layer by scratching it with hard objects, as disrupting its continuity significantly reduces its corrosion protection.

Welding fume management: Strict adherence to OHS regulations, forced ventilation and personal protection (e.g. P100 rated particle masks) are essential.

Prevention of “white rust”: Condensation can cause wet storage rust (white rust) to occur on the zinc layer if galvanized sheets are stacked close together and in a humid environment after processing or during storage. Ensure good ventilation, isolation (e.g. use of matting) and avoid prolonged open storage in the rain. Minor white rust usually does not affect long-term corrosion protection, but does affect appearance.

Post-treatment: Welded or damaged areas need to be repaired for corrosion protection (e.g. by spraying with zinc-rich primer).

Strong and corrosion-resistant everywhere

The finished galvanized steel sheet is widely used for its excellent strength-to-weight ratio and superior corrosion resistance in the following applications:

Building structures: roofs, walls, ventilation ducts, cable trays, lightweight steel structures.

Automobile industry: body chassis parts, fuel tanks, exhaust system parts.

Home appliance shell: washing machine, refrigerator, air conditioning outdoor unit.

Agricultural equipment: grain silos, agricultural machinery parts.

Public facilities: street light poles, traffic signs, guardrails.

China galvanized sheet metal fabrication manufacturer is a precision art that combines material science and advanced manufacturing technology. Understanding the properties of the base material, mastering key cutting, forming and joining techniques, and tightly controlling zinc protection and welding safety are the keys to successfully navigating this important engineering material. When engineers use lasers to carve the first precise cut lines in galvanized steel, when bending machines give flat plates their three-dimensional sinews, and when welding sparks bloom safely under strong ventilation - the sturdy backbone of modern industry gradually takes shape in these precise processes.

Galvanized steel is silent and tough, building an invisible rust-proof Great Wall under architectural domes, in the body of a speeding car, and in the metal casing of a home appliance. Every cut, bend and weld is a dialog between human wisdom and the power of metal, and in the eternal covenant between zinc and iron, the most enduring guardianship poem in industrial manufacturing is written.