Comprehensive Guide to Our Custom Sheet Metal Services

In the world of manufacturing and product development, the ability to create precise, durable, and custom metal components is paramount. At Houdry, we specialize in transforming raw sheets of metal into high-quality, functional parts that power industries and bring innovative ideas to life. This comprehensive guide will walk you through everything you need to know about our custom sheet metal service in China, from the initial design to the final finishing touch.

What is Custom Sheet Metal Fabrication?

At its core, sheet metal fabrication is a set of manufacturing processes that shape flat sheets of metal (such as steel, aluminum, or stainless steel) into specific parts and structures. "Custom" means that every step—from the initial cut to the final bend—is tailored to a client's unique design, specifications, and application requirements. It's a versatile solution for creating everything from simple brackets to complex enclosures for aerospace, automotive, medical, and telecommunications equipment.

Our Core Service Offerings

We are a custom sheet metal service manufacturer in China. Our comprehensive service portfolio ensures we can handle your project from concept to completion.

1. Cutting and Profiling:

This is the first step, where we cut the large metal sheet down to a more manageable size and shape. We utilize several advanced techniques to ensure precision and efficiency:

Laser Cutting: Ideal for complex geometries and intricate patterns, our high-powered laser cutters deliver exceptional accuracy and a clean, burr-free edge with a minimal heat-affected zone.

CNC Punching: Perfect for high-volume production of parts that require standard-shaped holes, slots, and notches. It's a fast and cost-effective method for less complex profiles.

Plasma Cutting: Best suited for cutting thicker sheets of conductive metals, offering a powerful and efficient solution for larger components.

2. Forming and Bending:

Once the part is cut, it often needs to be formed into a three-dimensional shape. Our state-of-the-art press brakes, operated by skilled technicians, allow us to create precise bends and angles.

We program our machines to account for bend deduction and springback, ensuring every angle meets your exact specifications.

We can handle a wide range of bend complexities, from simple boxes to parts with multiple flanges and intricate forms.

3. Joining and Welding:

For assemblies requiring multiple components, we offer professional joining services.

TIG (Tungsten Inert Gas) Welding: Provides high-precision, clean, and strong welds, perfect for stainless steel and aluminum, often used in applications where aesthetics and structural integrity are critical.

MIG (Metal Inert Gas) Welding: A faster welding process ideal for thicker materials and longer production runs, offering a strong and durable bond.

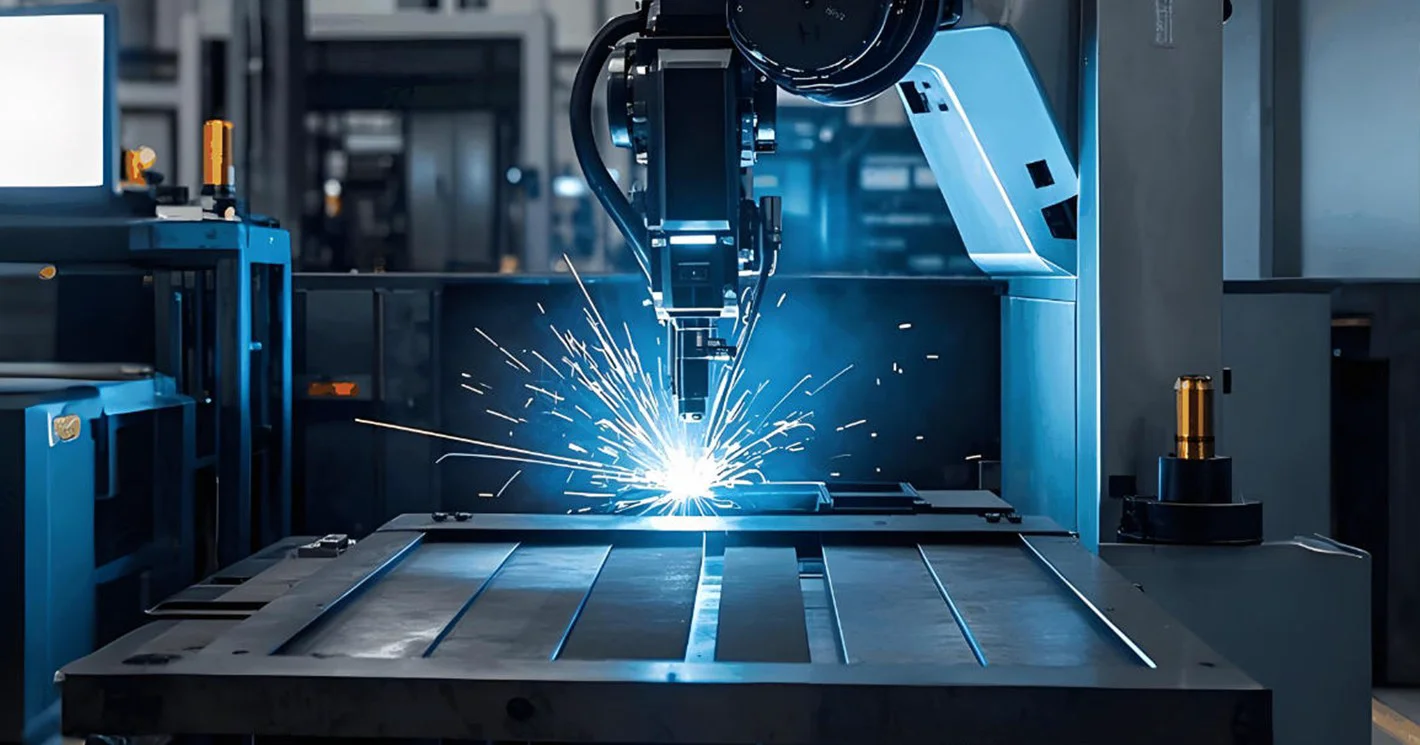

Robotic Welding: For repeatable, high-volume projects, our robotic welders ensure consistent, high-quality welds with unmatched speed and precision.

4. Finishing and Assembly:

The final appearance and properties of a part are often determined in the finishing stage. We offer a full suite of finishing services to protect your product and enhance its look:

Deburring and Surface Finishing: We smooth all edges and surfaces to remove sharp burrs and prepare the metal for coating.

Powder Coating: A durable, environmentally friendly, and aesthetically pleasing finish available in a vast array of colors and textures. It provides excellent resistance to corrosion, chipping, and scratching.

Anodizing: Primarily for aluminum, anodizing creates a hard, protective oxide layer that is highly resistant to corrosion and wear, and can be dyed in various colors.

Full Assembly: We can take your project a step further by providing complete assembly services, including the installation of hardware, rivets, and threaded inserts, delivering a ready-to-use product.

Why Choose Us?

Precision and Expertise: With years of industry experience, we have the knowledge to handle even the most challenging projects.

State-of-the-Art Technology: We invest in the latest machinery to guarantee efficiency, consistency, and high quality.

Commitment to Quality: Our unwavering dedication to quality control means you receive parts you can depend on.

Collaborative Partnership: We see ourselves as an extension of your team, providing expert support from design to delivery.

Ready to Start Your Project?

Whether you need a single prototype or a full production run, Houdry is your trusted partner for custom sheet metal fabrication China. Contact us today for a free, no-obligation quote and let us help you build the future, one precise part at a time.