- Contact Us

-

Contact: Devin Liu

E-mail: sales@sheetmetal-fabrication.com

Tel: +86 13382165719

Wechat: LGQ4169719 Contact Now

Contact Now

- New Products

- Latest News

-

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the custom design and fabrication of stainless steel, iron, aluminum, galvanized sheet and other materials. The fabricatio...what is advantage of anodic oxidation and anodized ?

Anodizing (spelled anodizing, in Singapore, the UK, India, and Australia) is an electrolytic passivation process used to increase the thickness of the...China Internation Furniture Fair 2017

From September 11 to 14, 2017, the 40th CIFF Shanghai will present a fantastic feast for the furniture and home furnishings industry. CIFF features th...How coronavirus impact global economy?

The coronavirus outbreak, which originated in China, has infected more than 200,000 people. Its spread has left businesses around the world counting c...

- Subscribe

-

Get email updates on new products

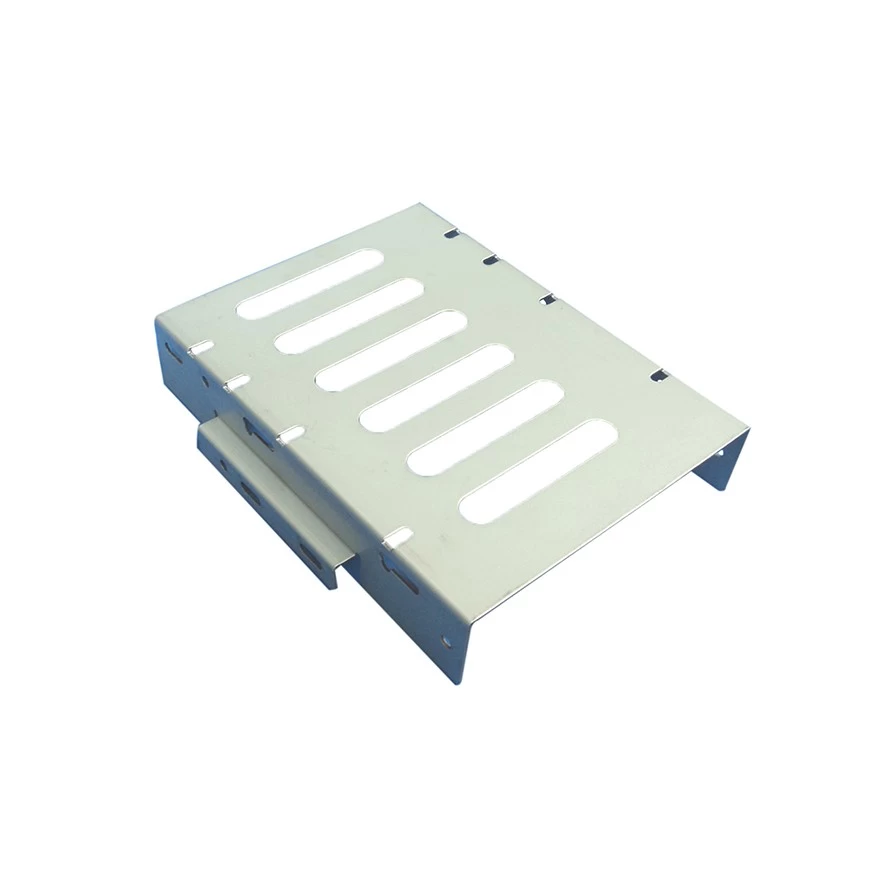

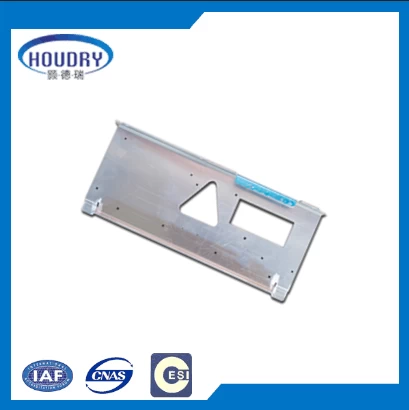

custom fabcicated sheet metal products for medical equipment

- Place of Origin:Jiangsu, China (Mainland)

- Brand Name:HOUDRY

- Model Number:Custom Made

- Certificate:ISO9001:2015/SGS

- Material:stainless steel

- Process:laser cutting/spot welding

- tolerance:0.01mm-0.1mm

- Surface treatment:mirror polishing/powder coated

- Service:OEM/ODM

- thickness:0.2mm-2.5mm

- Drawing format:CAD/JPEG/DWG/PDF/PRO/E

- Sample order:Sample order is acceptable

- Supplier type:manufacturer/fabcicator/factory/designer

- Packaging detail standard package/individual package for export or as requested

- Delivery time 7 - 20 working days or negotiable

- Item sheet metal parts

- Manufacturing process laser cutting/stamping/polishing

- Material stainless steel

- Surface treatment mirror polishing,powder coat, zinc plate,paint,brushing as per drawing.

- Thickness of part 0.5mm-16.0mm

- Tolerance ±0.1mm

- Package: standard package/individual package for export or as requested

- Certificates: ISO 9001:2015 /SGS

- Shipping: by ocean, by express, by air

- Payment term Fist order:T/T30% in advance, T/T 70% against copy of B/L or L/C

- Major markets North America,West Europe,Australia

|

Item |

sheet metal fabrication work |

|

Mould |

Tooling in house Mould charge is allowed in advance for special parts After certain quantity , we can return to you |

|

Product include |

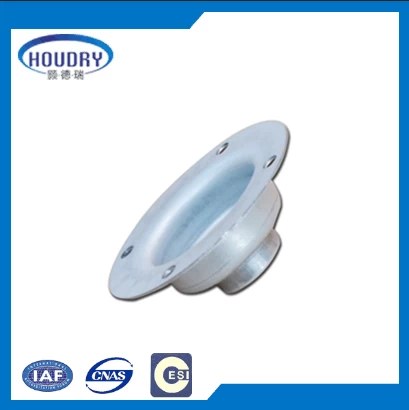

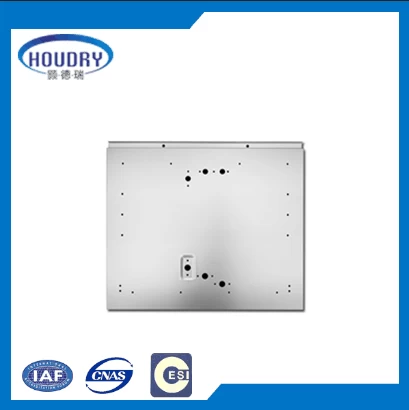

varieties of metal stamping parts, metal press stamping parts, metal welding parts, metal drawing parts, metal punch parts, CNC Metal parts, CNC metal machining parts, CNC metal machined parts, CNC metal milling aluminum parts, CNC metal turning stainless steel parts, Metal chassis, metallic cabinets, metal cabinets, metal cases, metal enclosures, metal boxes metallic machinery casing, metallic communication products, metallic auto parts, metallic refrigerator parts, metallic washing machine parts, vending machine shell fabrication, communication cabinet fabrication, mold designing making and so on. |

|

Material available |

Carbon steel (CRS/SPCC, SECC,etc),Stainless steel, spring steel, Bronze (berylium, phosphor, etc), brass, copper alloy, aluminum alloy, tinplate, nickel silver, |

|

Surface treatment available |

zinc/nickel/chrome/tin plating(colour or natural), Galvanization, anodizing, oil spraying, powder coating, polishing, passivate, brush, wire drawing, etc. |

|

Metal processing available |

Stamping mould

sheet metal fabrication work: tooling making, samples approval, cutting, stamping, punching, tapping, welding, bending and forming, finishing, assembly; CNC parts: CNC lathe milling, CNC lathe turning, drilling, tapping, finishing, assembly, packing |

|

Specification |

OEM/ODM, according to customer's drawing or sample |

|

Tolerance |

Stamping parts:0.01-0.1mm, CNC machining parts:0.1-0.002mm |

|

Service available |

Before mass production, we supply pre-production samples for customer final confirmation, tooling maintenance and tooling slight change free |

|

Packing |

Inner packing : polybag ; Outer packing : export cartons ; Customized packing available . |

|

Delivery |

By sea or by air;the delivery date is according to specific orders Usually within 30 days after receiving 30% down payment |

|

Payment |

First order:T/T 30% in advance, T/T 70% against copy of B/L or L/C |

What can Houdry do?

>>We have professional technical team,can help you with product design.

>>Our production involves the CNC machining and sheet metal,welding,

laser cutting,wire cutting,deep drawing etc.can help you with complex

processing products.

>>Stable support for heat treatment and various surface treatment to

meet customer s overall requirements.

>>High quality and accuracy lead time

How we ensure the quality?

>>Once the order release,technology department will study the whole

processing and attention according to customers requirements,and make

the QC schedule,SIP,improve the decompose drawings of each process,

call all department together to emphasis each process control point.

>>Quality control inspecting during all the production from raw material

purchasing,production,surface treatment and package,so they can amend

in time once issue happened.

Tel:8613382165719

Wechat:LGQ4169719

Facebook:ahlgq2000@163.com

Contact Person:Devin Liu

PDF Show:PDF