- Contattaci

-

Contatto: Devin Liu

E-mail: sales@sheetmetal-fabrication.com

Tel: 86 13382165719

WeChat: LGQ4169719 Contatta ora

Contatta ora

- Nuovi Prodotti

-

Armadi di stoccaggio in stile industriale per la fabbricazione di pannelli in lamiera del fornitore della Cina

Armadietto da ufficio industriale personalizzato per la finitura della fabbricazione di metalli in fabbrica in Cina

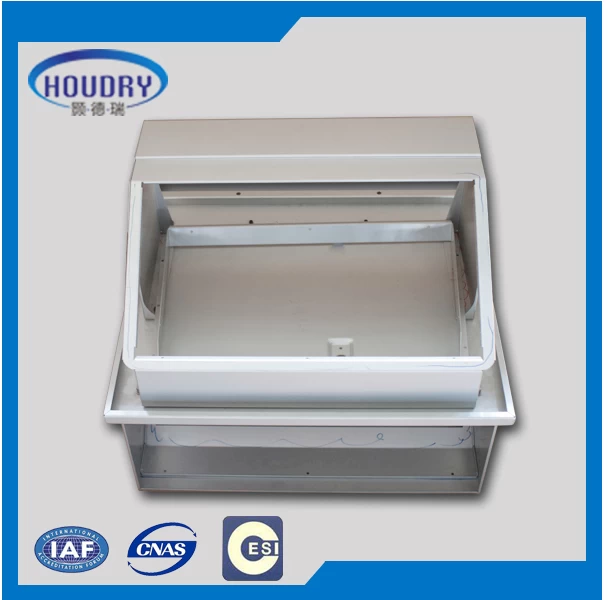

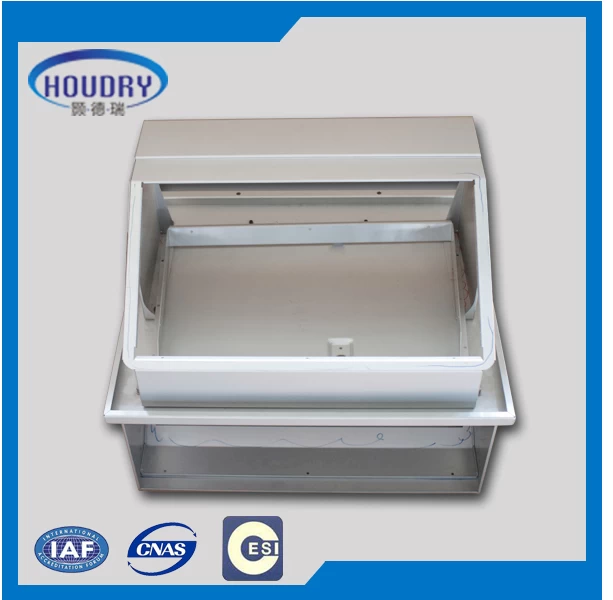

Produttore cinese di fabbricazione di lamiere Progettazione di stampaggio di lamiere-x-Luogo di origine: Jiangsu, Cina (continente)Marchio: HOUDRYNumero di modello: su misuraCertificato: ISO9001:2015/SGSMateriale: acciaio inossidabile/ferro/alluminio

Armadi per negozi in acciaio per armadietti per parti in lamiera per carichi pesanti-x-Luogo di origine: Jiangsu, Cina (continente)Marchio: HOUDRYNumero di modello: su misuraCertificato: ISO9001:2015/SGSMateriale: acciaio inossidabile/ferro/alluminio

Produttore cinese di parti in lamiera per armadi di stoccaggio in metallo industriale-x-Luogo di origine: Jiangsu, Cina (continente)Marchio: HOUDRYNumero di modello: su misuraCertificato: ISO9001:2015/SGSMateriale: acciaio inossidabile/ferro/allumini

Armadi di stoccaggio industriali con cassetti per la lavorazione della lamiera del produttore cinese

- Ultime notizie

-

Che cos'è la fabbricazione di lamiere?

La fabbricazione di lamiere è la progettazione e la fabbricazione su misura di acciaio inossidabile, ferro, alluminio, lamiera zincata e altri materiali. La fabbricazione...qual è il vantaggio di ossidazione anodica e anodizzato?

L'anodizzazione (anodizzazione del farro, a Singapore, nel Regno Unito, in India e in Australia) è un processo di passivazione elettrolitica utilizzato per aumentare lo spessore del...Cina Internazionale mobili fiera 2017

Dall'11 al 14 settembre 2017, il quarantesimo CIFF Shanghai presenterà una fantastica festa per l'industria del mobile e dell'arredo domestico. CIFF ...In che modo il coronavirus influisce sull'economia globale?

L'epidemia di coronavirus, che ha avuto origine in Cina, ha infettato più di 200.000 persone. La sua diffusione ha lasciato le aziende di tutto il mondo contando c...

- sottoscrivi

-

Ricevi aggiornamenti via e-mail sui nuovi prodotti

Popular custom aluminum alloy metal fabrication Suzhou china

- All kinds of metal materials available,include steel,aluminum,copper,brass,stainless steel etc.

- Completely equipments include cutting,bending,stamping,CNC,welding etc.

- Various surface treatment support such as power coating,anodizing,polishing,plating etc.

- Strict quality control system,IQC,IPQC,OQC etc.

|

tem |

sheet metal fabrication work |

|

Mould |

Tooling in house Mould charge is allowed in advance for special parts After certain quantity , we can return to you |

|

Product include |

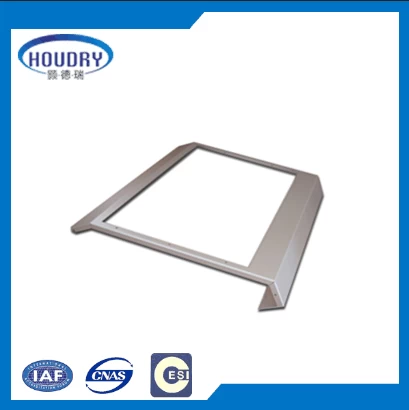

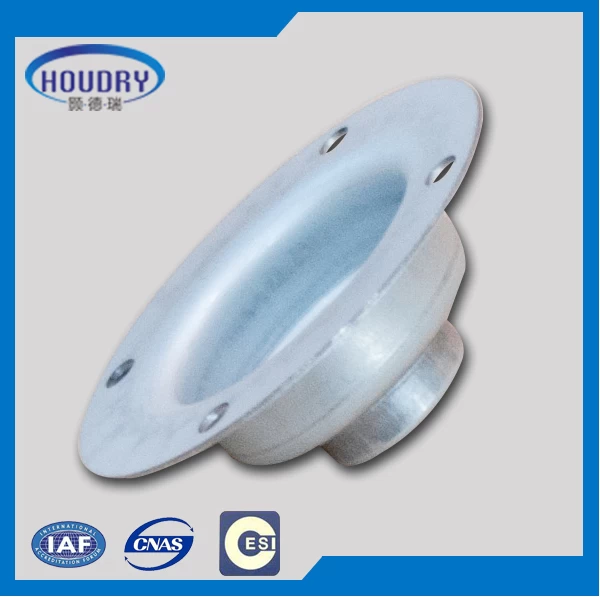

varieties of metal stamping parts, metal press stamping parts, metal welding parts, metal drawing parts, metal punch parts, CNC Metal parts, CNC metal machining parts, CNC metal machined parts, CNC metal milling aluminum parts, CNC metal turning stainless steel parts, Metal chassis, metallic cabinets, metal cabinets, metal cases, metal enclosures, metal boxes metallic machinery casing, metallic communication products, metallic auto parts, metallic refrigerator parts, metallic washing machine parts, vending machine shell fabrication, communication cabinet fabrication, mold designing making and so on. |

|

Material available |

Carbon steel (CRS/SPCC, SECC,etc),Stainless steel, spring steel, Bronze (berylium, phosphor, etc), brass, copper alloy, aluminum alloy, tinplate, nickel silver, |

|

Surface treatment available |

zinc/nickel/chrome/tin plating(colour or natural), Galvanization, anodizing, oil spraying, powder coating, polishing, passivate, brush, wire drawing, etc. |

|

Metal processing available |

Stamping mould

sheet metal fabrication work: tooling making, samples approval, cutting, stamping, punching, tapping, welding, bending and forming, finishing, assembly; CNC parts: CNC lathe milling, CNC lathe turning, drilling, tapping, finishing, assembly, packing |

|

Specification |

OEM/ODM, according to customer's drawing or sample |

|

Tolerance |

Stamping parts:0.01-0.1mm, CNC machining parts:0.1-0.002mm |

|

Service available |

Before mass production, we supply pre-production samples for customer final confirmation, tooling maintenance and tooling slight change free |

|

Packing |

Inner packing : polybag ; Outer packing : export cartons ; Customized packing available . |

|

Delivery |

By sea or by air;the delivery date is according to specific orders Usually within 30 days after receiving 30% down payment |

|

Payment |

First order:T/T 30% in advance, T/T 70% against copy of B/L or L/C |

What can Houdry do?

>>We have professional technical team,can help you with product design.

>>Our production involves the CNC machining and sheet metal,welding,

laser cutting,wire cutting,deep drawing etc.can help you with complex

processing products.

>>Stable support for heat treatment and various surface treatment to

meet customer s overall requirements.

>>High quality and accuracy lead time

How we ensure the quality?

>>Once the order release,technology department will study the whole

processing and attention according to customers requirements,and make

the QC schedule,SIP,improve the decompose drawings of each process,

call all department together to emphasis each process control point.

>>Quality control inspecting during all the production from raw material

purchasing,production,surface treatment and package,so they can amend

in time once issue happened.

Tel:8613382165719

Chatta:LGQ4169719

Facebook:ahlgq2000@163.com

Referente:Devin Liu

PDF Show.:PDF