Six steps of sheet metal processing

Yummy Yao

2015-07-22 12:48:41

Our common sheet metal processing, mainly consists of several steps:

Sheet metal processing drawing design > laser processing or (CNC pressed) > bend > welding > electrostatic powder spraying or (liquid paint) > packaging and shipment

Design of sheet metal processing: General customer drawings or samples, from my company who are standard designs, expand, eventually forming the process decomposition and Assembly submitted to the production process.

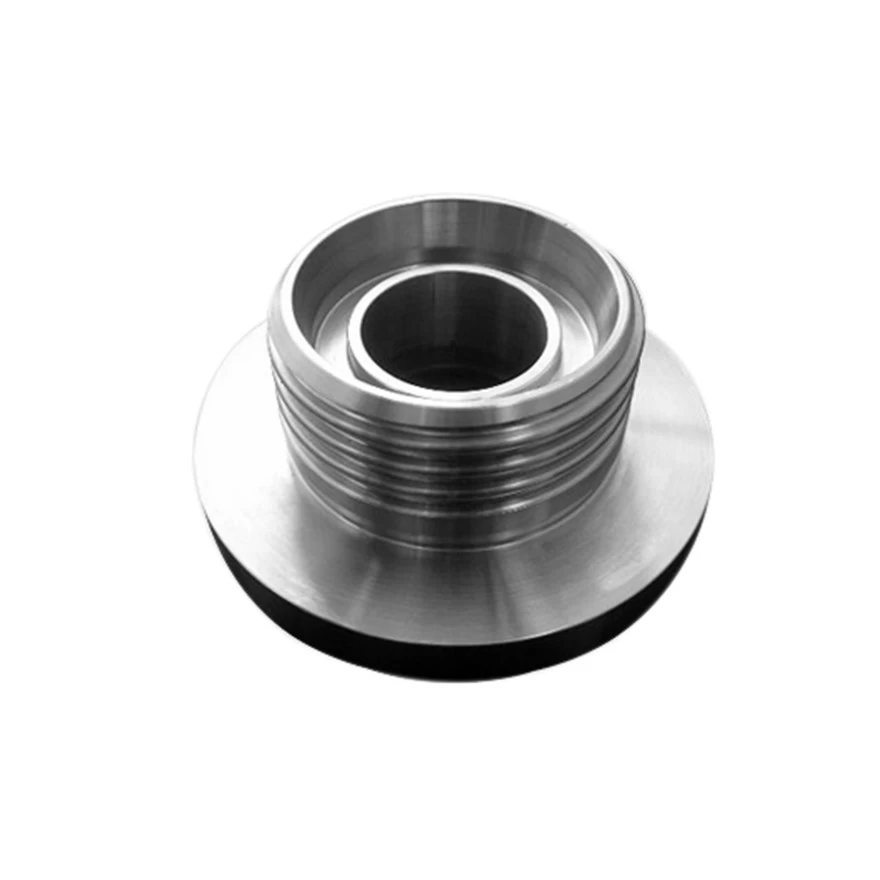

Laser processing of sheet metal processing: the company has 2500 Watt laser cutting machine, cutting materials such as carbon steel, stainless steel material using laser cutting material, machining section clean and smooth after beautiful, dimensional precision, workpiece edge with arc, General CNC punching is no substitute for processing.

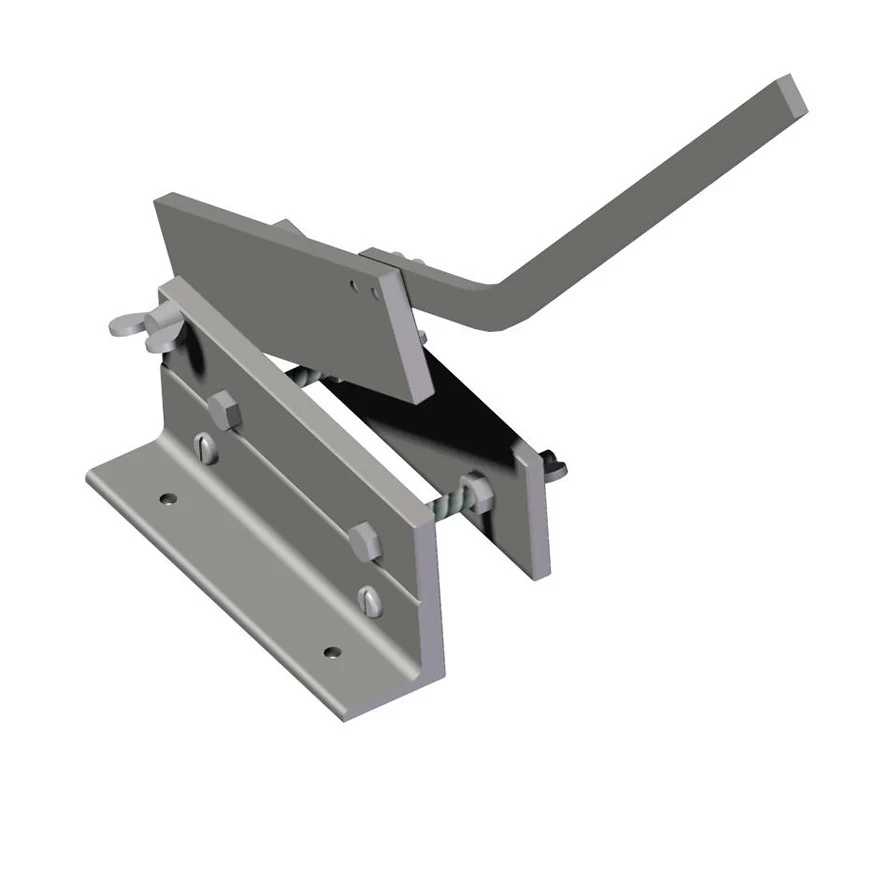

CNC stamping: NC Press mainly according to material thickness of thin products, generally is more suitable for 2.5mm materials, more or need to open a special mold machining holes (punch and die) to processing of workpieces, larger batch of used CNC stamping has some cost advantage.

Bending: well after the feeding of the workpiece, such as bend forming the most need, the company has more than one computer bending machine, not only fast, processing more accurate, for the subsequent welding Assembly provides a good guarantee.

Welding forming: artifacts in Xia good material Hou general need assembled forming, assembled way has variety, some directly with screws, and pulled riveting, non-welding process forming, this forming method more simple, environmental, split solutions easy, but exists design complex, structure enough firm, appearance enough beautiful, so general mechanical shell not take this class assembled way, this class compared for furniture class, Office products, general mechanical shell sheet metal gold more using welding forming, company General take argon arc welding, touch welding, carbon dioxide welding,, After soldering the workpiece is polished, so that the workpiece is very stable and beautiful.

Electrostatic spray powder: electrostatic spray powder main for carbon steel quality artifacts, stainless steel General welding Hou main with alcohol cleaning welding parts Hou on no longer need for processing has, but iron pieces because easy rust, so need for surface processing, in process Shang General first for except oil except rust, table adjustable cleaning, p of processing, electrostatic spray powder, high temperature baking, process, processing Hou artifacts surface beautiful (color, figure lines can itself select), number years not rust, cost low, advantages.

Liquid paint: this process there are differences and electrostatic powder spraying, General work, in the case of not handling liquid paint a convenient to use, low cost advantages of liquid paint is generally divided into two steps, above the workpiece processing primer paint.

Sheet metal processing drawing design > laser processing or (CNC pressed) > bend > welding > electrostatic powder spraying or (liquid paint) > packaging and shipment

Design of sheet metal processing: General customer drawings or samples, from my company who are standard designs, expand, eventually forming the process decomposition and Assembly submitted to the production process.

Laser processing of sheet metal processing: the company has 2500 Watt laser cutting machine, cutting materials such as carbon steel, stainless steel material using laser cutting material, machining section clean and smooth after beautiful, dimensional precision, workpiece edge with arc, General CNC punching is no substitute for processing.

CNC stamping: NC Press mainly according to material thickness of thin products, generally is more suitable for 2.5mm materials, more or need to open a special mold machining holes (punch and die) to processing of workpieces, larger batch of used CNC stamping has some cost advantage.

Bending: well after the feeding of the workpiece, such as bend forming the most need, the company has more than one computer bending machine, not only fast, processing more accurate, for the subsequent welding Assembly provides a good guarantee.

Welding forming: artifacts in Xia good material Hou general need assembled forming, assembled way has variety, some directly with screws, and pulled riveting, non-welding process forming, this forming method more simple, environmental, split solutions easy, but exists design complex, structure enough firm, appearance enough beautiful, so general mechanical shell not take this class assembled way, this class compared for furniture class, Office products, general mechanical shell sheet metal gold more using welding forming, company General take argon arc welding, touch welding, carbon dioxide welding,, After soldering the workpiece is polished, so that the workpiece is very stable and beautiful.

Electrostatic spray powder: electrostatic spray powder main for carbon steel quality artifacts, stainless steel General welding Hou main with alcohol cleaning welding parts Hou on no longer need for processing has, but iron pieces because easy rust, so need for surface processing, in process Shang General first for except oil except rust, table adjustable cleaning, p of processing, electrostatic spray powder, high temperature baking, process, processing Hou artifacts surface beautiful (color, figure lines can itself select), number years not rust, cost low, advantages.

Liquid paint: this process there are differences and electrostatic powder spraying, General work, in the case of not handling liquid paint a convenient to use, low cost advantages of liquid paint is generally divided into two steps, above the workpiece processing primer paint.