How Important is Sheet Metal Laser Cutting in Sheet Metal Fabrication?

What Is Sheet Metal Laser Cutting?

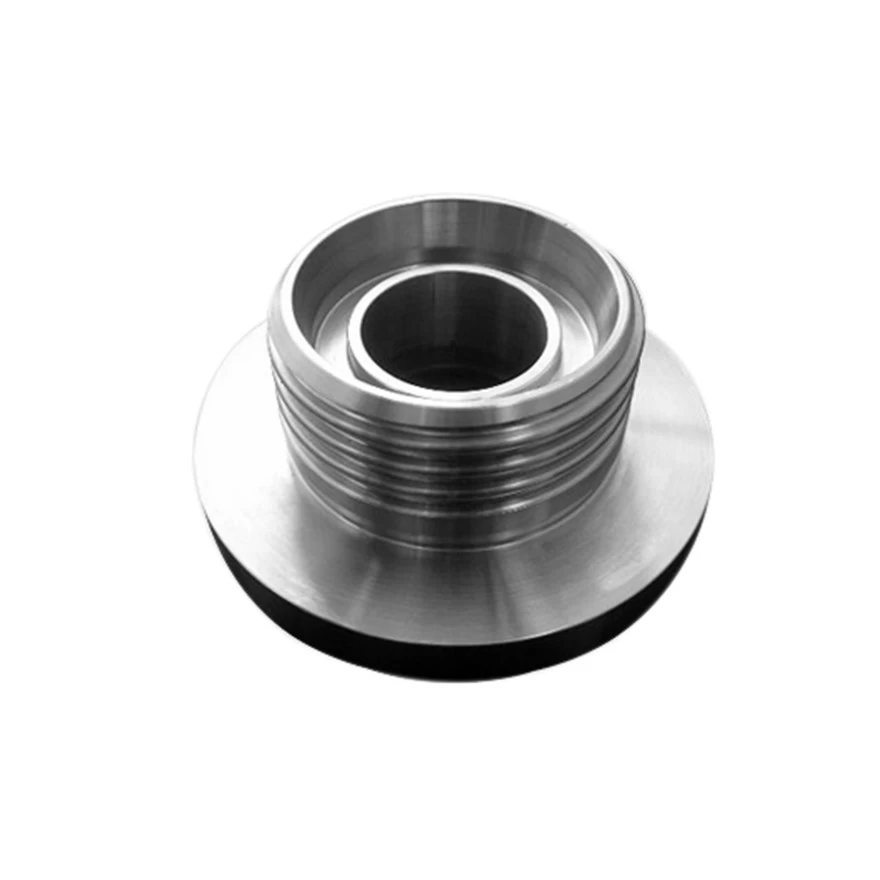

Sheet metal laser cutting is a process in which a high-powered laser beam is used to cut through sheet metal material. The laser beam is focused on a specific point on the sheet metal, causing the material to melt, burn, or vaporize and create a precise cut. This method is highly accurate and can be used to cut complex shapes and designs in various types of sheet metal, including steel, aluminum, and stainless steel. The process is often used in industries such as automotive, aerospace, electronics, and construction for manufacturing parts, components, and prototypes.

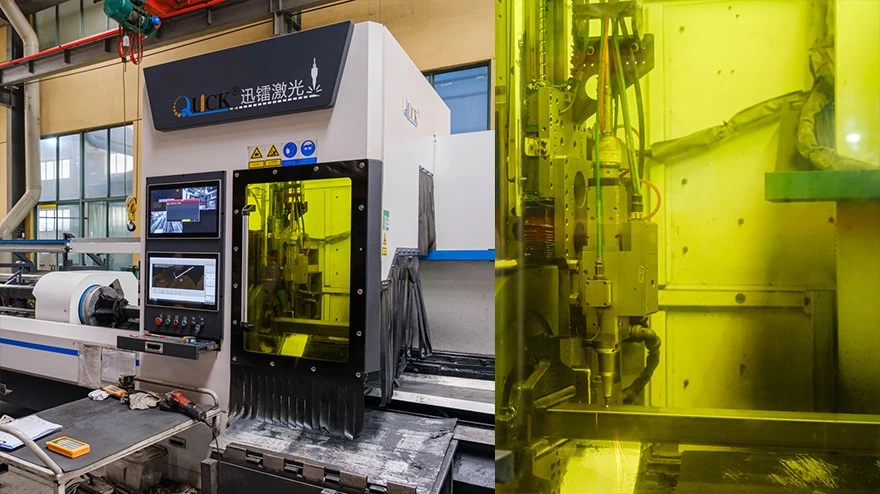

Sheet metal fabrication China supplier use laser cutting machines to cut and shape sheet metal materials with precision and efficiency. How China Sheet Metal Fabrication Manufacturer’s Laser Cutting Machines Work?

1. Laser Beam Generation: The laser cutting machine uses a high-powered laser beam, typically generated by a CO2 laser, to cut through the sheet metal. The laser beam is created by exciting a gas mixture inside a sealed tube, resulting in the emission of a high-energy beam of light.

2. Beam Delivery System: The laser beam is directed through a series of mirrors and lenses to focus it into a small, concentrated spot. The beam delivery system ensures that the laser beam remains stable and accurately positioned on the material being cut.

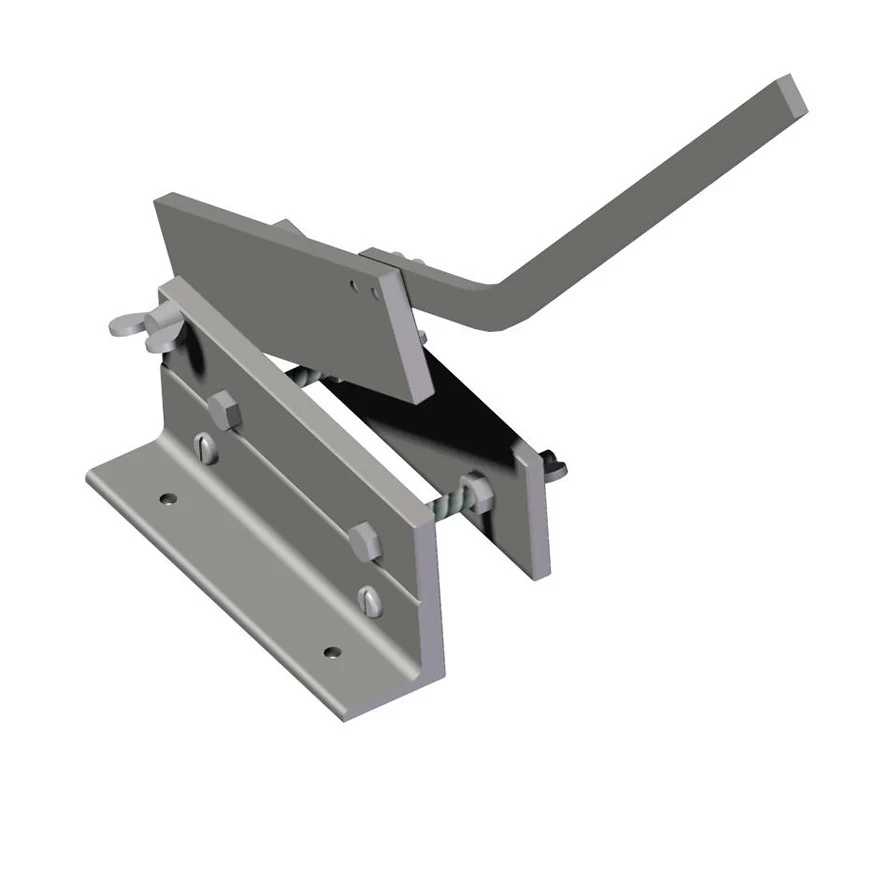

3. Material Preparation: The sheet metal material is prepared by placing it on a cutting bed or table. The material may be clamped or held in place using vacuum suction to prevent movement during the cutting process.

4. Cutting Parameters: The operator sets the cutting parameters such as laser power, cutting speed, and focus distance based on the material type, thickness, and desired cutting quality. These parameters determine the intensity and speed of the laser beam during the cutting process.

5. Cutting Process: Once the material is properly positioned and the cutting parameters are set, the laser cutting machine begins the cutting process. The focused laser beam is directed onto the sheet metal, rapidly heating and melting the material at the point of contact.

6. Material Removal: As the laser beam moves along the programmed cutting path, it vaporizes or melts the material along the cutting line. The molten or vaporized material is blown away by a high-pressure gas jet, typically compressed air or nitrogen, which is directed through a nozzle positioned near the laser beam.

7. CNC Control System: The laser cutting machine is controlled by a computer numerical control (CNC) system. The operator uses specialized software to program the desired cutting path and other cutting parameters. The CNC system controls the movement of the laser beam and the cutting bed, ensuring precise and accurate cutting.

8. Quality Control: Throughout the cutting process, the laser cutting machine may incorporate various quality control measures. These include sensors that monitor the cutting process, ensuring that the laser beam remains focused and aligned correctly. Additionally, the CNC system may perform real-time adjustments to maintain consistent cutting quality.

9. Finishing and Post-Processing: After the cutting process is complete, the sheet metal may undergo further finishing or post-processing steps, such as deburring, bending, or welding, to achieve the desired final product.

China sheet metal laser cutting manufacturers utilize laser cutting machines to achieve precise and efficient cutting of sheet metal materials, enabling them to produce high-quality products for various industries.