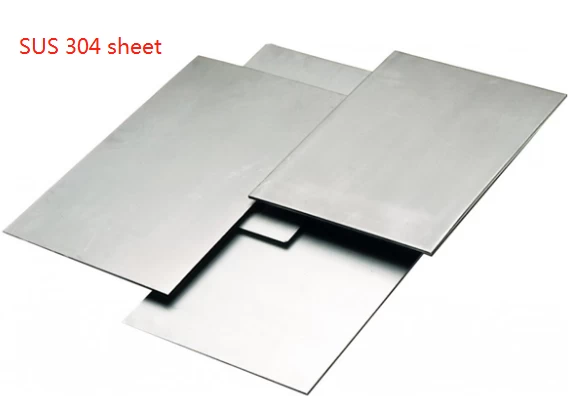

SUS 304, with its chromium-nickel content and low carbon, is the most versatile and widely used of the austenitic stainless steels. Its alloys are all modifications of the 18% chromium, 8% nickel austenitic alloy. SUS 304 proves to be resistant to oxidation, corrosion, and durability. All provide ease of fabrication and cleaning, prevention of product contamination offer a variety of finishes and appearances.SUS 304 are used in corrosion resistant electrical enclosures, auto molding and trim, wheel covers, kitchen equipment, hose clamps, exhaust manifolds, stainless hardware, storage tanks, pressure vessels and piping.

SUS 316 stainless steel is an austenitic chromium-nickel stainless and heat-resisting steel with superior corrosion resistance as compared to other chromium-nickel steels when exposed to many types of chemical corrodents such as sea water, brine solutions, and the like. SUS316 alloy contains molybdenum bearing it has a greater resistance to chemical attack than 304. Type 316 is durable, easy-to-fabricate, clean, weld and finish. It is considerably more resistant to solutions of sulfuric acid, chlorides, bromides, iodides and fatty acids at high temperature. Stainless steels containing molybdenum are required in the manufacture of certain pharmaceuticals in order to avoid excessive metallic contamination. The bottom line is that Type 316 stainless steel costs a little more upfront but you could save a whole lot on the back end – especially if your enclosure is going to be used outdoors.