What Are The Advantages of Sheet Metal Laser Cutting?

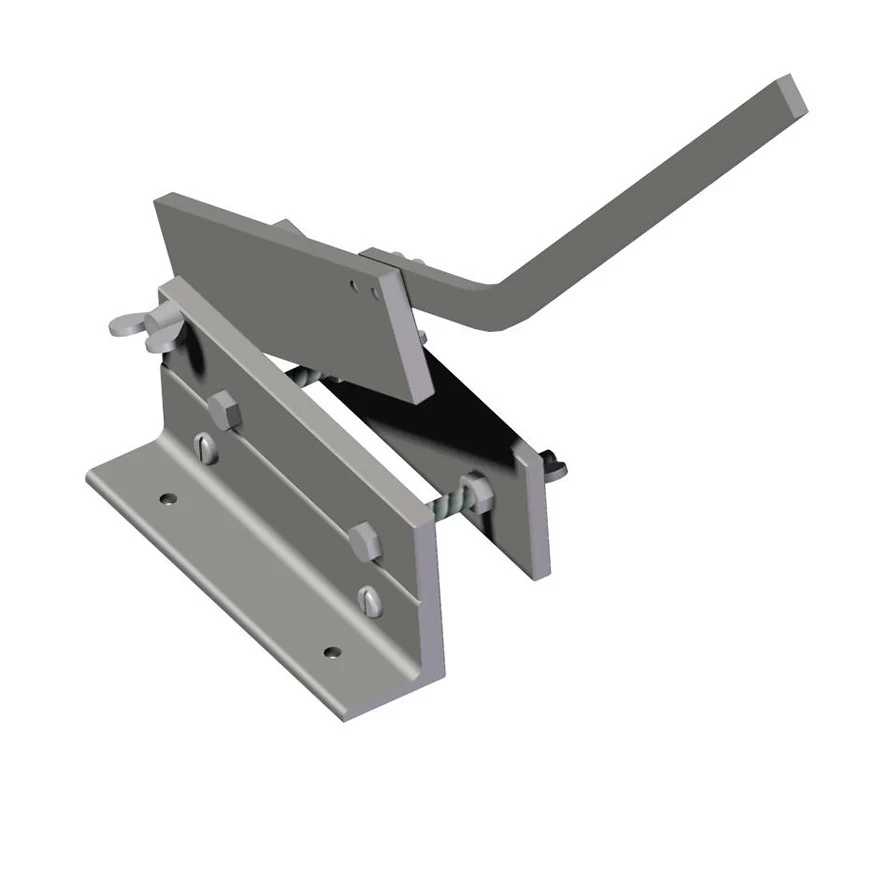

Compared with the traditional plate-cutting method, China laser-cutting fabrication has obvious advantages. Its advantages are mainly manifested in precision, versatility, speed, clean and smooth cutting, low material loss, flexibility, automation and so on.

China Laser cutting fabrication is a fast process, with fast cutting speed, shortens turnaround time and improves production efficiency, reduces production time and cost; cutting has high precision and accuracy, can cut complex designs with minimal error, narrow kerf, which A high-quality finished product is ensured.

Laser-cutting materials have good applicability and can be used for a variety of materials, including various types of metals, plastics, wood, etc. This makes it a versatile cutting method for different industries and applications. Good material applicability can also reduce tool wear. Whether it is a simple or complex part, it can be cut with a laser for precise rapid prototyping, and the cutting surface does not have any burrs or rough linearity. It is very clean and smooth, reducing the need for additional finishing processes need.

In the process of custom sheet metal fabrication in China, no matter what processing technology is applied, material loss will occur, and laser cutting of sheet metal in China is a precise cutting method that can minimize material waste, and the laser beam is focused on a specific cutting line, reducing the amount of material wasted during cutting. Laser cutting machines can be fully automated, reducing labor and improving efficiency. The production cost is reduced and the economic benefit is good.

Laser cutting machines are controlled by computer programming, so can be programmed to cut various shapes and designs, making it a flexible cutting method for different project requirements, which allows customization and the ability to create complex patterns and designs. This is very suitable for the sheet metal processing industry because sheet metal fabrication is a customized processing product.

Laser cutting is achieved by applying high power density energy generated by laser focusing. Under the control of the computer, the laser is discharged through the pulse, so as to output the controlled repetitive high-frequency pulse laser to form a beam with a certain frequency and a certain pulse width. The pulse laser beam is transmitted and reflected by the optical path and focused on the surface of the processed object, tiny, high-energy-density light spots are formed, and the focal spot is located near the surface to be processed, melting or vaporizing the processed material at an instantaneous high temperature. Each high-energy laser pulse instantly sputters a small hole on the surface of the object. Under the control of the computer, the laser processing head and the material to be processed perform continuous relative motion according to the pre-drawn graphics, so that the object will be processed. desired shape.

Laser cutting of sheet metal offers precision, versatility, speed and efficiency, making it the cutting method of choice in a variety of industries including automotive, aerospace, electronics and more. Every sheet metal processing product is tailored according to your requirements. No matter what material or shape you want, our China sheet metal fabrication supplier can meet your requirements.