China Manufacturer Sheet Metal Welding Service

What Is Sheet Metal Welding?

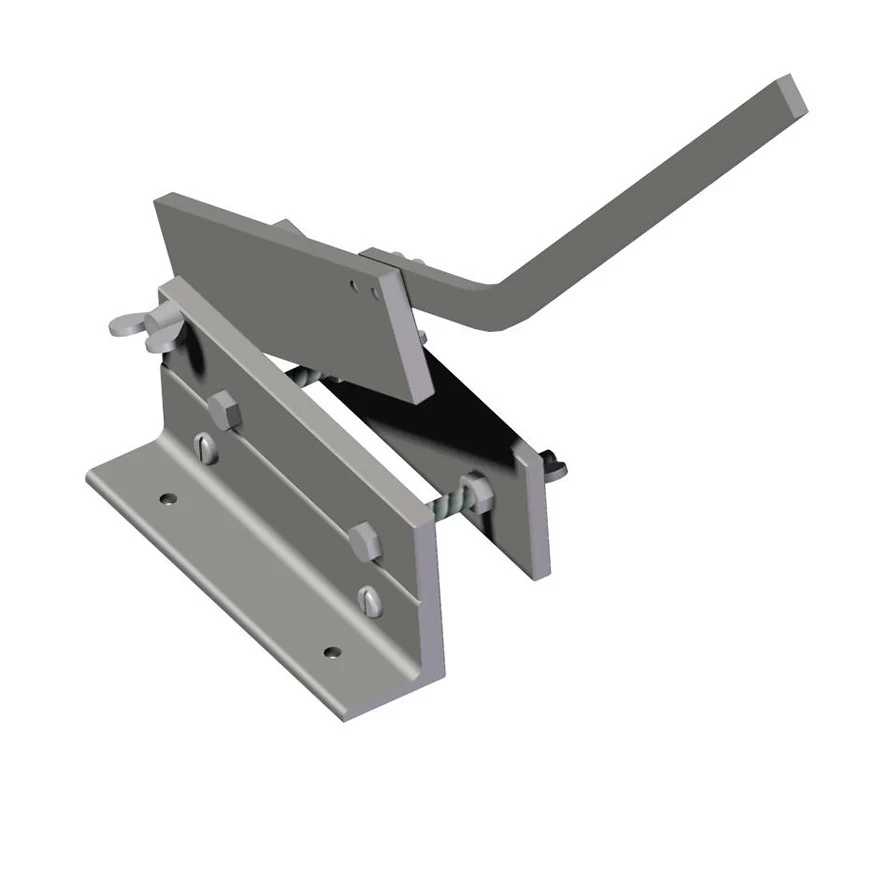

Sheet metal welding is a process in sheet metal fabrication. During sheet metal welding, heat and pressure are used to join two or more metal plates together. It involves melting the edges of metal sheets to create a molten pool, which is then allowed to solidify and bond the sheets together.

There are many different techniques for sheet metal fabrication and welding such as arc welding, spot welding, and laser welding sheet metal etc. Sheet metal fabrication manufacturers can improve sheet metal welding services, and Houdry Company can also provide customers with sheet metal welding services of different technologies.

Different Materials for Sheet Metal Welding - welding stainless steel sheet metal

Stainless steel is a very popular material for welding sheet metal. It has excellent corrosion resistance and is suitable for different environments and industries.

Laser welding in Welding stainless steel sheet metal can be used for stainless steel materials of various thicknesses. Generally speaking, laser welding stainless steel sheet can weld thin stainless steel plates as thin as a few hundred microns, and can also weld stainless steel components up to several millimeters thick.

Different Materials for Sheet Metal Welding - welding aluminium sheet metal

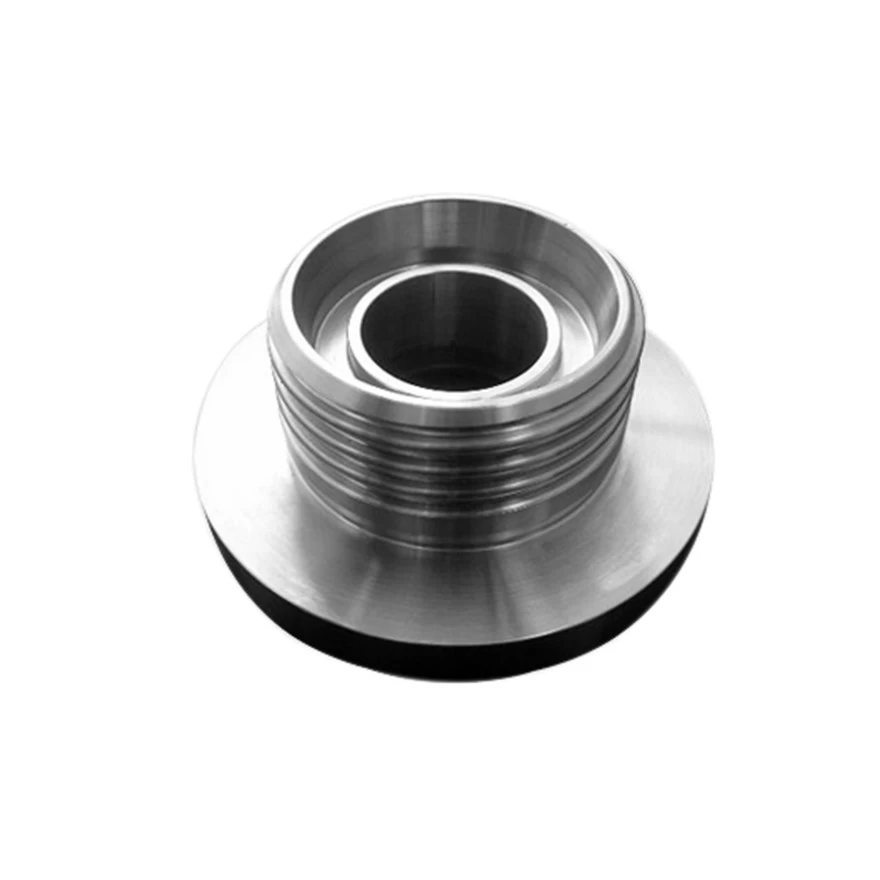

Aluminum is a lightweight material often used for sheet metal welding. It has a good strength-to-weight ratio and is commonly used in the aerospace and automotive industries.

Aluminum sheet metal profiles are widely used in various welded structural products due to their lightweight, high strength, good corrosion resistance, non-magnetic, good formability and good low-temperature properties. Aluminum sheet welding profiles are used to replace thick By welding sheet metal materials, the structural weight can be reduced by more than 50%. Welding aluminium sheet metal mainly uses MIG welding, which is the most suitable welding method.

Advantages of Sheet Metal Welding

1. Strength: Sheet metal welding creates strong and durable joints that can withstand high levels of stress and load.

2. Versatility: Sheet metal welding can be used to join a wide range of metals, including steel, aluminum, and stainless steel, making it a versatile joining method.

3. Cost-effective: Sheet metal welding is a cost-effective joining method, as it requires minimal additional materials or components.

4. Aesthetics: Welded sheet metal joints can have a clean and seamless appearance, enhancing the overall aesthetic of the finished product.

5. Efficiency: Sheet metal welding is a fast and efficient joining method, allowing for quick production and assembly of metal components.

6. Design flexibility: Welding allows for greater design flexibility, as it can be used to create complex and intricate shapes and structures.

7. Corrosion resistance: Welded sheet metal joints can have excellent corrosion resistance, especially when using corrosion-resistant metals or protective coatings.

8. High precision: Sheet metal welding can achieve high levels of precision and accuracy, ensuring that the joints meet the required specifications.

9. Longevity: Properly welded sheet metal joints can have a long lifespan, withstanding the test of time and maintaining their structural integrity.